- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 14, 2025 01:29 Back to list

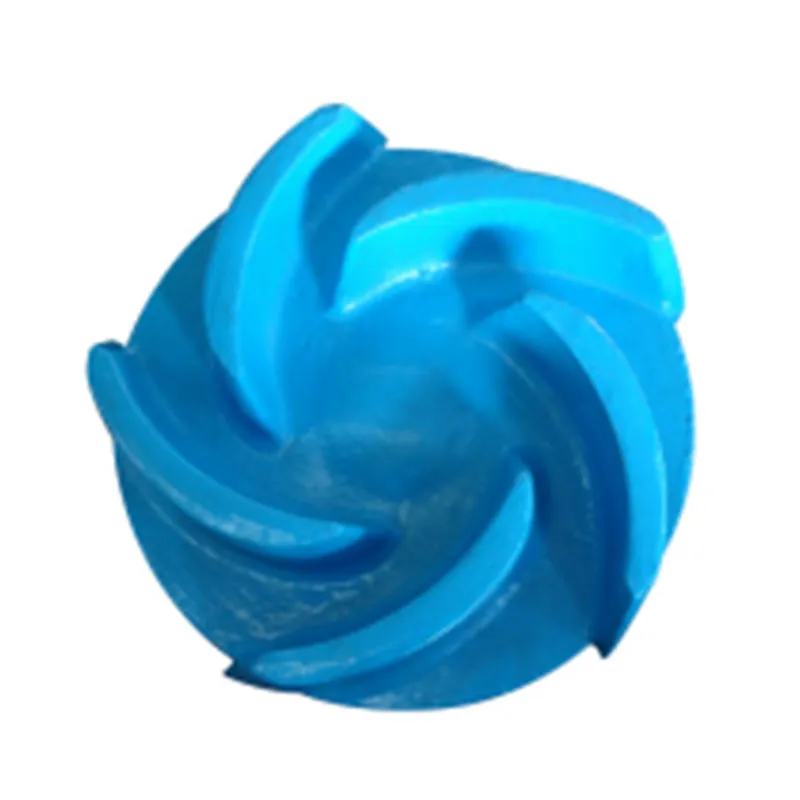

rompión de titanio.

The authoritative knowledge base, compiled through years of innovation and trial, places brands like Sandvik and Kennametal at the forefront of the titanium drilling landscape. These companies, leveraging vast R&D resources, have pioneered multi-purpose drills that cater specifically to the aerospace and automotive sectors. Their domination in this niche stems from a well-earned reputation, enshrined through impeccable adherence to quality standards and the consistent rollout of updated, groundbreaking products. Furthermore, the integration of smart technology into titanium drilling systems showcases an authoritative leap in methodological precision. Sensors embedded in advanced machinery now provide real-time data analytics that interpret feedback such as vibration, temperature, and force resistance, adjusting operational parameters instantaneously. Such intelligent systems represent the vanguard of engineering innovation; a testament to the industry's authoritative stance in technological application. Trustworthiness Certification, Testing, and Quality Assurance The reliability and trustworthiness of titanium drilling rely heavily on rigorous certification and quality assurance processes. Each tool undergoes extensive testing governed by international benchmarks such as ISO and ASTM standards. To gain the trust of consumers and industrial players, manufacturers subject their products to stringent testing cycles that replicate the toughest drilling scenarios, ensuring not just compliance but exceeding expectations. The credibility of a titanium drilling tool is corroborated by its certification history—endorsed by third-party evaluators whose assessments authenticate the quality promised. Material grades and production batches are meticulously documented, ensuring traceability and accountability in every facet of production. This comprehensive focus on quality fortifies the trust clients place in these companies, fostering enduring partnerships built upon unwavering excellence. In Conclusion Titanium rompión denotes more than just a product enhancement; it signifies a robust industry transformation where innovation, expertise, authority, and trust coalesce to reshape possibilities. The confluence of superior materials engineering, cutting-edge design, and rigorous quality assurance defines the future of titanium drilling. As industries continue to push boundaries, the advancements encapsulated in titanium rompión assure a future where complexity is seamlessly navigated with precision and reliability, driving unparalleled growth and success.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025