- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 20, 2025 08:26 Back to list

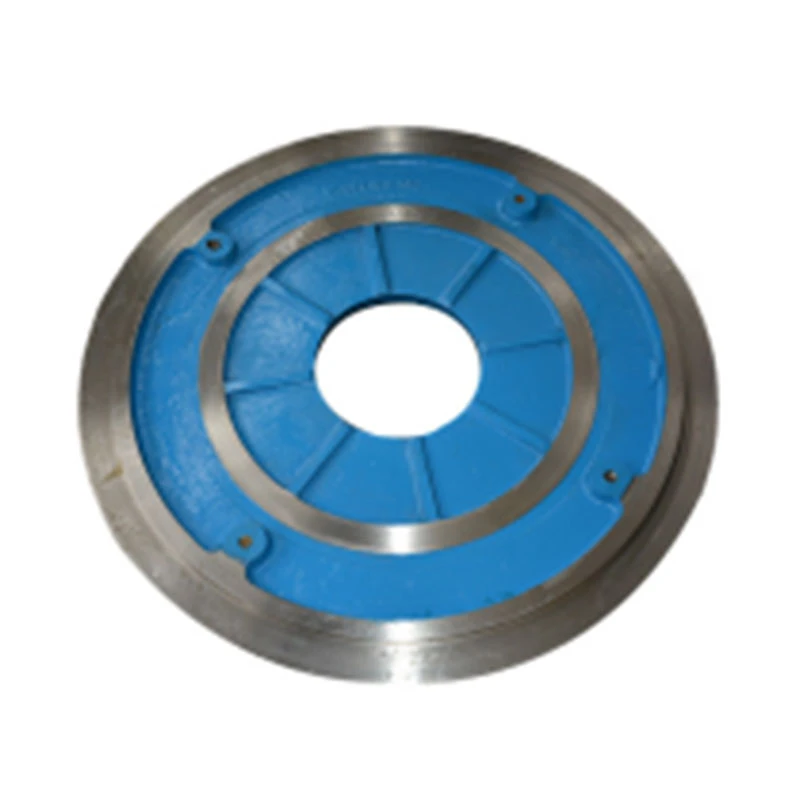

jaw crusher plate material

In recent years, composite materials combining the best properties of different metals have emerged as advantageous alternatives. For example, bimetallic alloys that integrate the toughness of steel with the high-wear resistance of chromium create a synergistic effect, offering enhanced performance compared to homogenous materials. These innovative materials showcase the advancements in metallurgical technology and underline the importance of continuous improvement in crushing operations. Non-metallic options such as ceramic-reinforced liners have also gained popularity. Ceramics provide exceptional wear resistance, with studies showing they can last multiple times longer than traditional metal plates. When embedded in a resilient matrix, they offer an unparalleled reduction in maintenance frequency. Their effectiveness is backed by engineering expertise and cutting-edge research that lend a strategic advantage in specialized applications demanding reduced downtime and uninterrupted operation. The selection of jaw crusher plate materials must also consider operational conditions such as the specific type of crushed material, the contact conditions, the production rates, and the financial implications of different material options. Determining this balance requires professional know-how and can benefit from consultations with material scientists and seasoned technicians who understand the intricacies of crusher operation and material performance. Ultimately, the credibility and authority of your choice stem from thorough research and collaboration with experts. Choosing the most appropriate jaw crusher plate material involves not just evaluating the properties of the materials but also understanding their performance in real-world conditions. By leveraging experience in the field and professional expertise, you can make informed decisions that enhance the reliability and efficiency of your crushing operations, ensuring sustained productivity and cost-effectiveness over time.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025