- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 14, 2025 11:54 Back to list

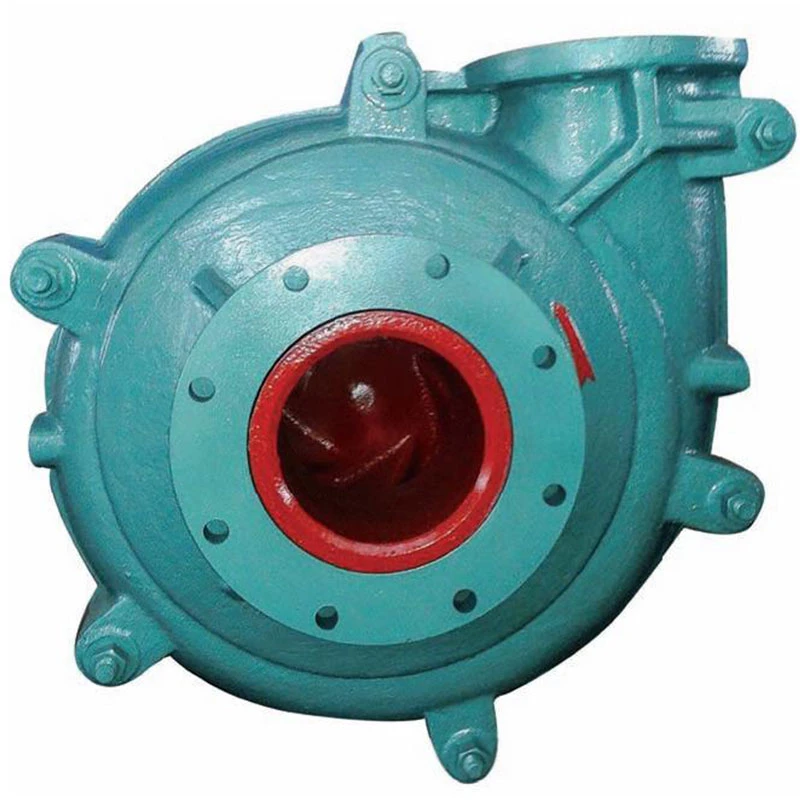

vertical mud pump

Furthermore, the vertical mud pump is celebrated for its energy efficiency. The modern designs focus on reducing energy consumption without sacrificing performance, aligning with the global shift towards more sustainable industrial practices. By integrating energy-efficient technologies, companies can significantly reduce their carbon footprint while saving on operational costs. Trust in vertical mud pumps is not merely based on their mechanical prowess; it stems from a proven track record across numerous successful drilling projects worldwide. Their repeatedly demonstrated ability to perform under pressure in different geological settings makes them a trusted choice for industry experts seeking reliability. For firms investing in these pumps, the long-term benefits are clear reduced operational disruptions, decreased operational costs, and compliance with safety and environmental standards. As the demand for energy continues to increase, the role of vertical mud pumps in ensuring effective and sustainable drilling operations cannot be overstated. In essence, vertical mud pumps are more than mere tools; they are cornerstones of modern drilling operations. Their expert design, authoritative capabilities, and trustworthiness make them indispensable assets in any rigorous exploration or extraction project. For stakeholders in the drilling industry, choosing the right pump translates to enhanced productivity and a solid return on investment.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025