- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 16, 2025 02:24 Back to list

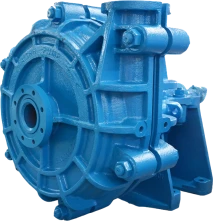

Zj Series Single-Stage, Single-Suction, Centrifugal Slurry Pump

Expertise in the field not only involves technical understanding but also familiarity with current industry trends and technological advancements. The integration of automation and AI technology into directional drilling equipment is a compelling trend, offering enhanced precision and reducing the need for human intervention. Machines equipped with advanced software provide predictive maintenance alerts, streamlining operations and minimizing downtime. For buyers, investing in such innovative technology can provide a competitive edge, enhancing operational efficiency and accuracy. Furthermore, the environmental considerations of drilling operations are becoming increasingly important, influencing purchase decisions. Many modern directional drilling rigs boast features that minimize their ecological footprint. These include systems designed to reduce drilling fluid use, minimize ground disturbance, and ensure efficient waste management. Selecting rigs from manufacturers committed to sustainable practices aligns with broader corporate social responsibility goals and can enhance a company’s reputation. The authoritative name brands in directional drilling offer products that combine reliability with cutting-edge technology. Companies such as Ditch Witch, Vermeer, and Herrenknecht have set industry benchmarks, providing a comprehensive range of equipment tailored to diverse operational needs. Their commitment to continuous innovation and client support ensures that buyers not only receive top-tier machines but also the necessary training and service support, fostering trust and long-term reliability. In summary, the sale of directional drilling rigs is a thriving sector, defined by technical excellence, innovative advancements, and a commitment to sustainability. Buyers must thoroughly assess their specific needs, from operational requirements to compliance with environmental standards, ensuring a sound investment that bolsters their drilling capacities. Embracing modern technologies and choosing reputable brands can assure that the purchase of directional drilling machines is both strategic and advantageous, paving the way for successful and efficient underground construction projects.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025