- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 10, 2025 09:25 Back to list

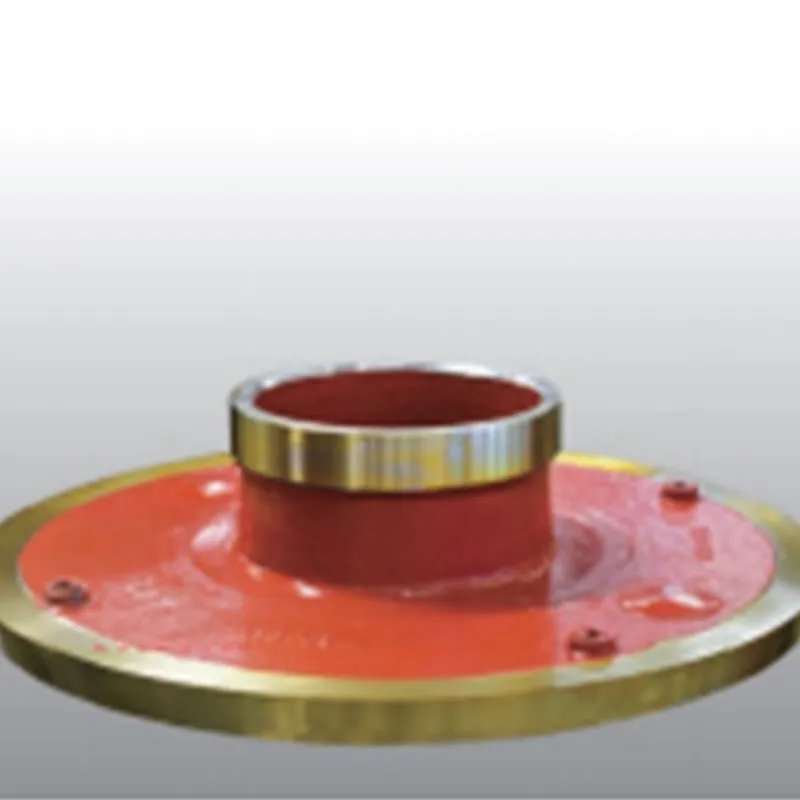

slurry pump types

Air-operated Double Diaphragm Pumps (AODD Pumps) enhance flexibility by using air to move the diaphragms and facilitate fluid transfer. Their portable, simple, and compact design allows for versatile applications, especially in environments where electricity is not accessible or where highly corrosive materials are involved. Industries like chemical processing frequently rely on AODD pumps due to their energy-efficient nature, reduced maintenance needs, and capability to handle shear-sensitive fluids. Progressive Cavity Pumps, recognized for their precise flow control capabilities, are indispensable in applications requiring gentle and steady flow regularity. They operate through a helical rotor within a double-helix elastomeric stator, allowing them to transfer slurry with minimal pulsation. Their aptitude for handling viscous and solid-laden materials without shear damage makes them particularly valuable in wastewater treatment and oil industry applications. Selecting the appropriate slurry pump hinges on a thorough understanding of the nature of the slurry, operational conditions, and specific usage requirements. Engineering insights and operational experiences must guide this selection to ensure maximum efficiency and reliability. As technology evolves, the development of more advanced and specialized slurry pumps continues to provide industries with tailored solutions, reinforcing the importance of remaining informed and proactive in pump selection strategies to optimize industrial processes and reduce costs.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025