- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 07, 2025 01:27 Back to list

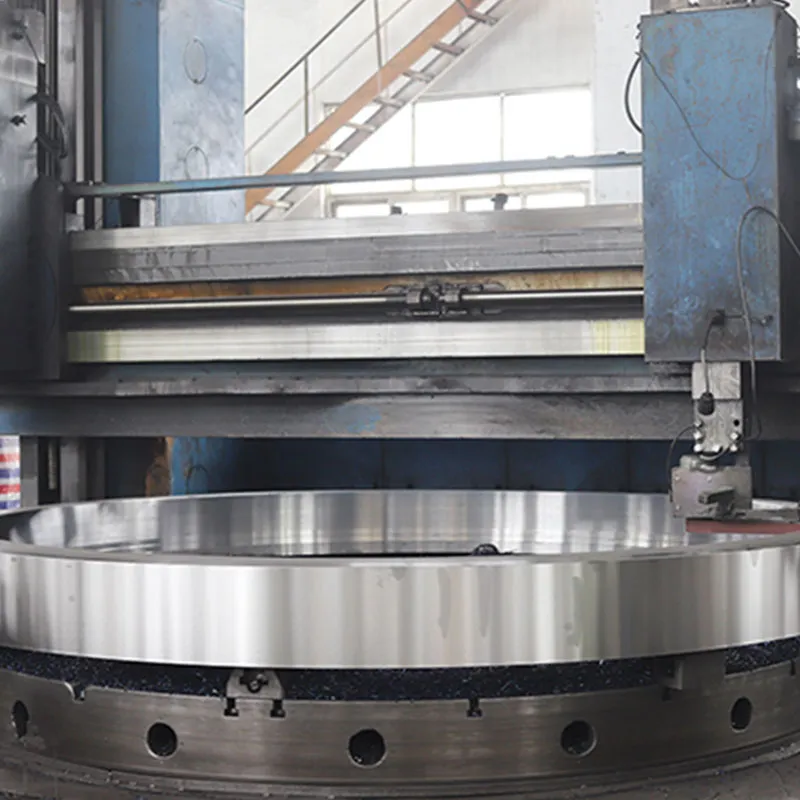

sludge pump impeller

A hallmark of trustworthy sludge pump impeller manufacturers is their commitment to rigorous testing and quality assurance. Reliability is verified through factory acceptance tests (FATs) which simulate real-world conditions to ensure the impeller meets all performance specifications before installation. This thorough testing process builds customer confidence and trust in product quality. Further, the shift towards sustainability and eco-friendly engineering designs has influenced the development of sludge pump impellers. Modern impellers are increasingly designed to minimize environmental impact by reducing energy consumption and maximizing throughput efficiency. This not only reflects current industry trends but also aligns with global efforts toward reducing carbon footprints, demonstrating a responsible and sustainable approach to product development. Finally, case studies and customer testimonials provide valuable insights into real-world performance and reliability of sludge pump impellers. Testimonials from reputable companies and case analyses documenting specific problem-solving instances reinforce the credibility and effectiveness of the product in practical applications. In conclusion, the sludge pump impeller is a critical component that exemplifies industrial expertise, commitment to quality, and innovative design. For stakeholders, investing time in understanding impeller materials, design configurations, and maintenance best practices yields substantial benefits in operational efficiency and reliability. Through a blend of solid engineering principles and trustworthy product development, the modern sludge pump impeller stands as a testament to the fusion of science and practical experience.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025