- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 11, 2025 04:32 Back to list

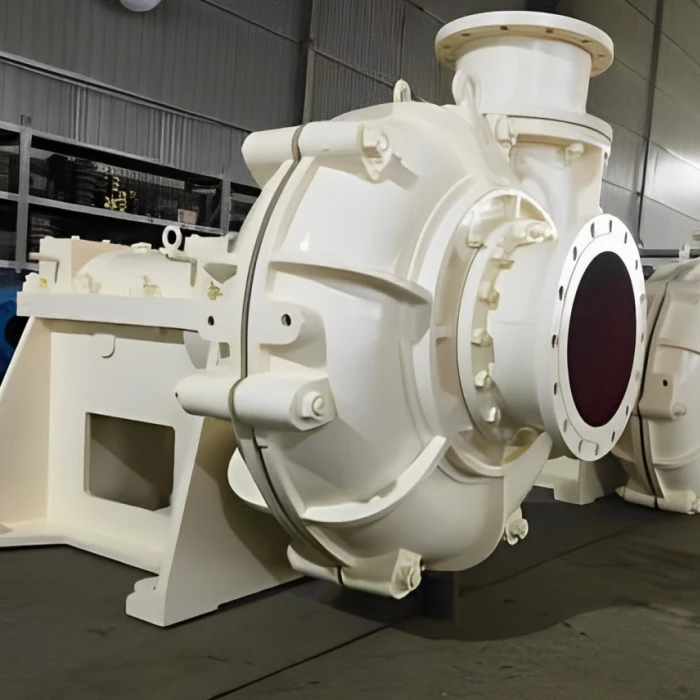

how to use a gravel pump

Authoritativeness in the context of mud pumps is often associated with leading manufacturers and industry standards organizations, who provide guidelines on their use, maintenance, and safety protocols. Notable manufacturers such as National Oilwell Varco, Halliburton, and Schlumberger have a storied history of producing reliable and effective mud pumps. They continually innovate with enhanced materials, improved pump designs, and integrated technologies for monitoring and diagnostics, which help operators preemptively address potential issues. Trustworthiness of information regarding mud pumps is largely dependent on the sources providing this knowledge. Industry publications, manufacturer training programs, and certifications from recognized bodies like the American Petroleum Institute (API) assure that the details on mud pump operation and maintenance are reliable. Such sources offer comprehensive insights into the newest technological advancements, safety standards, and environmental considerations in mud pump utilization. A technically sound understanding of a mud pump's workings furthers sectoral knowledge and operational competence. The pump’s ability to withstand harsh operational environments while maintaining fluid circulation efficiency is a testament to its engineering. Proper utilization and maintenance of these pumps not only enhance their longevity but also ensure project efficiency and environmental safety. Consequently, for industries reliant on such technology, investing in education and best practices related to mud pumps is crucial for sustainable operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025