- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 19, 2025 23:25 Back to list

jaw crusher parts

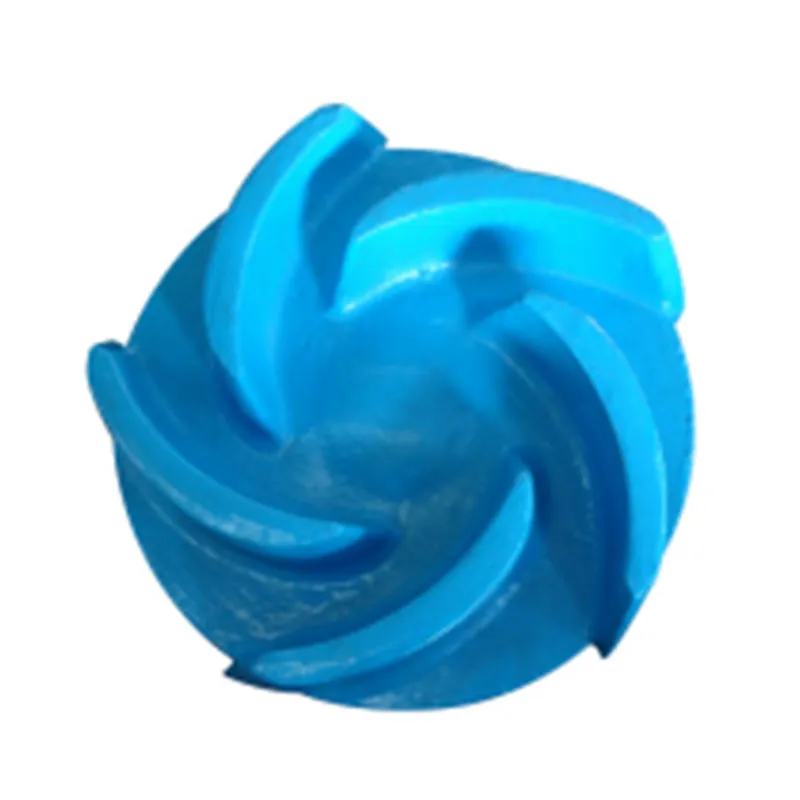

The flywheel is a part often overlooked but fundamental to the jaw crusher's efficiency. Acting as an energy reservoir, it maintains the machine’s balance and stabilizes its velocity during idle times. A well-balanced flywheel decreases power consumption while enhancing overall machine efficiency. Industry expertise suggests evaluating the flywheel's integrity regularly and ensuring it is free from damage or wear to maintain optimal performance. Superior lubrication and sealing of bearings cannot be overstated. Bearings facilitate the smooth motion of the crusher, and using high-quality lubricants ensures their longevity. Proper seals prevent dust and debris from contaminating the lubricant, which can lead to premature wear. Professionals prioritize ethylene-propylene-diene-monomer (EPDM) synthetic rubber seals as they provide excellent protection and last longer under extreme conditions. For anyone vested in the operational excellence of jaw crushers, the above insights are indispensable. Experience in maintaining and using quality parts translates to improved performance, lower maintenance costs, and increased machine life. Beyond parts, a holistic approach to machine upkeep is paramount. Adopting preventive maintenance schedules, investing in quality training for operators, and choosing reputable suppliers for components all enhance a crusher's performance. When selecting suppliers, a keen understanding of their reputation and expertise is critical. Trustworthy suppliers stand behind their products, providing warranties and comprehensive support. In conclusion, the meticulous selection, inspection, and maintenance of jaw crusher parts are integral to maximizing efficiency and reliability. Professionals in the industry leverage their expertise to differentiate between substandard and superior components, building trust through outstanding results. By focusing on the quality and maintenance of each component, one can ensure the jaw crusher not only meets but exceeds its performance expectations, solidifying its role as a cornerstone of industrial material processing.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025