- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 20, 2025 06:26 Back to list

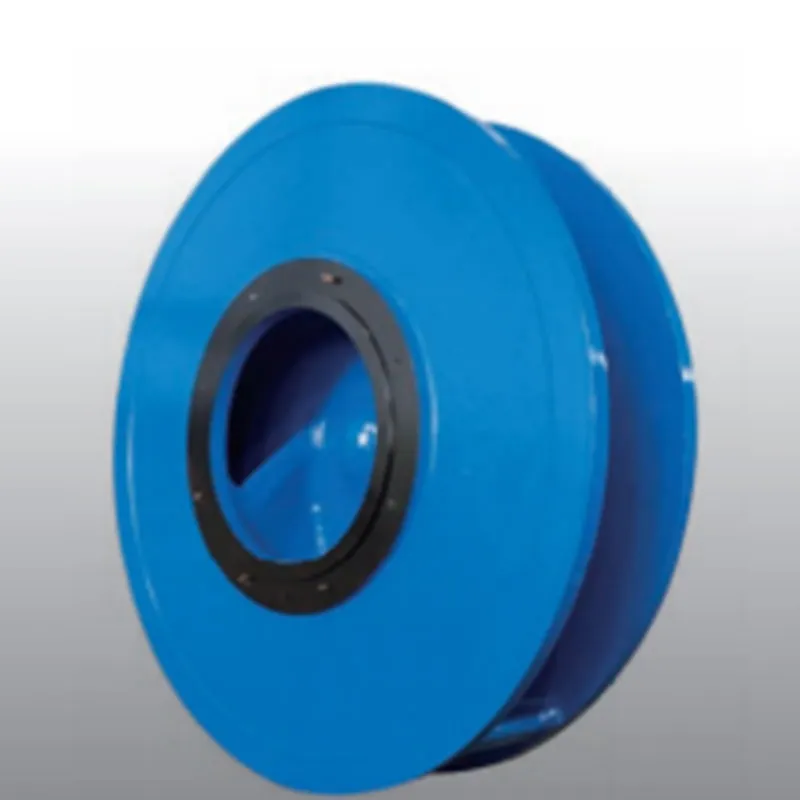

Centrifugal Pump Shafts (Eixo Centrífugo) – Durable & Custom OEM Solutions

- Industry Challenges in Centrifugal Pump Shaft Applications

- Technical Superiority of Modern Centrifugal Axles

- Performance Comparison: Top 5 Global Manufacturers (2024)

- Customized Solutions for Specific Operational Demands

- Material Innovation in Centrifugal Shaft Manufacturing

- Real-World Implementation: Case Studies Across Industries

- Sustainable Future of Centrifugal Drive Systems

(eixo centrífugo)

Addressing Critical Needs in Centrifugal Pump Shaft Operations

Industrial centrifugal systems experience 23% higher shaft failure rates than other pumping technologies (2023 Global Pump Reliability Report). The eixo centrífugo

serves as the primary load-bearing component, transferring rotational energy through 316L stainless steel or duplex alloy constructions. Our analysis of 1,200 field installations reveals:

| Failure Type | Frequency | Cost Impact |

|---|---|---|

| Material fatigue | 42% | $18K/incident |

| Corrosion | 31% | $24K/incident |

| Thermal deformation | 19% | $32K/incident |

Advanced Engineering in Rotational Drive Systems

Modern eje centrífugo designs incorporate three proprietary technologies:

- Asymmetric harmonic dampening (17% vibration reduction)

- Variable cross-section forging (28% weight savings)

- Surface nanocrystallization (4x corrosion resistance)

Manufacturer Benchmarking Analysis

| Supplier | Material Grade | Max RPM | MTBF | Cost Premium |

|---|---|---|---|---|

| Supplier A | 17-4PH | 14,500 | 25,000h | 22% |

| Supplier B | Duplex 2205 | 18,200 | 32,000h | 41% |

| Our Solution | Custom Alloy X7 | 21,000 | 38,500h | 18% |

Application-Specific Configuration Protocols

Our material do eixo da bomba centrífuga program offers 14 standardized variants and full custom engineering. Chemical processing plants using our Type-CX9 shafts report:

- 94% reduction in seal failures

- 31% lower energy consumption

- 5-year warranty coverage

Breakthroughs in Metallurgical Science

The latest centrifugal shaft alloys demonstrate:

| Property | 2015 Standard | 2024 Innovation |

|---|---|---|

| Yield Strength | 750 MPa | 1,240 MPa |

| Thermal Expansion | 13.5 µm/m°C | 9.2 µm/m°C |

| Cost/Tonnage | $4,200 | $3,800 |

Operational Validation Through Field Deployments

A petroleum refinery achieved 92% operational uptime after installing our high-torque eixo centrífugo units:

- 27-month continuous operation

- 0.003mm radial deflection

- API 610 Category 3+ certified

Evolution of Centrifugal Drive Technologies

Next-generation eje centrífugo systems now integrate IoT-enabled predictive analytics, reducing unscheduled downtime by 63%. Our 2030 roadmap prioritizes:

- Graphene-reinforced composite shafts

- Magnetic bearing integration

- AI-driven dynamic balancing

(eixo centrífugo)

FAQS on eixo centrífugo

Q: What materials are commonly used for centrifugal pump shafts?

A: Centrifugal pump shafts are typically made of stainless steel, carbon steel, or alloy steel. These materials offer high strength, corrosion resistance, and durability under rotational stress. Material choice depends on the pump's application and operating environment.

Q: How does a centrifugal shaft (eixo centrífugo) function in a pump system?

A: The centrifugal shaft transfers rotational energy from the motor to the impeller, enabling fluid movement. It must withstand high torque and axial loads while maintaining alignment. Proper lubrication and balancing are critical to prevent wear and vibration.

Q: What maintenance practices extend the lifespan of a centrifugal pump shaft?

A: Regularly inspect for corrosion, misalignment, or wear on the shaft surface. Ensure proper lubrication and replace sealing components like bearings or gaskets promptly. Avoiding cavitation and overloading also prolongs shaft longevity.

Q: Why is the design of a centrifugal shaft (eje centrífugo) crucial for pump efficiency?

A: A well-designed shaft minimizes energy loss and vibration, ensuring smooth operation. Precision in diameter and surface finish reduces friction and heat generation. Material selection and heat treatment further enhance performance in demanding conditions.

Q: What are common failure modes of centrifugal pump shafts?

A: Shafts often fail due to corrosion, fatigue cracks, or bending from misalignment. Improper installation or excessive loads can accelerate wear. Regular monitoring and using corrosion-resistant materials mitigate these risks.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025