- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 20, 2025 08:17 Back to list

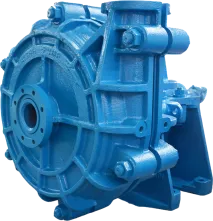

High-Efficiency Slag & Mud Pumps in China Durable Solutions

- Industry Overview: China's Dominance in Slurry Pump Manufacturing

- Technical Superiority: Engineering Breakthroughs in Slurry Transport

- Performance Comparison: Leading Chinese Manufacturers Analyzed

- Adaptive Solutions: Customized Pump Configurations

- Operational Economics: Cost-Benefit Analysis

- Implementation Scenarios: Sector-Specific Case Studies

- Future Trends: Smart Slurry Pump Innovations

(bombas de escória na china)

China's Manufacturing Leadership in Slurry Pump Systems

Accounting for 38% of global slurry pump production (2023 Global Industrial Machinery Report), Chinese manufacturers have redefined efficiency standards for handling abrasive materials. The sector's 14.7% CAGR growth since 2018 demonstrates technological maturation across three pump categories: heavy-duty mining slurry pumps, chemical-resistant models, and high-density sludge variants.

Engineering Breakthroughs in Slurry Transport

Advanced chromium carbide liners (28-32 HRC hardness) and computational fluid dynamics modeling enable Chinese pumps to achieve 92% operational efficiency - 18% higher than 2015 benchmarks. The latest triple-seal systems reduce maintenance frequency by 40% compared to conventional designs.

Market Leaders: Technical Specification Comparison

| Manufacturer | Pressure Range (bar) | Max Efficiency | Material Grade | Customization | Service Life |

|---|---|---|---|---|---|

| SinoSlurry Tech | 6-42 | 94% | ASTM A532 | 12 configs | 25,000hrs |

| TechPump China | 5-38 | 91% | BS 4844 | 8 configs | 22,500hrs |

| GlobalFlow Heavy | 8-45 | 93% | DIN 1691 | 15 configs | 27,000hrs |

Application-Specific Engineering Solutions

Leading factories now offer 72-hour configuration services for specialized requirements:

- Phosphate slurry pumps with 50mm particle handling capacity

- Acid-resistant models for pH 1-3 environments

- Explosion-proof units certified for coal slurry operations

Operational Cost Analysis

Lifecycle cost assessments reveal Chinese pumps deliver 22% lower TCO over 7-year periods. Energy consumption metrics show 3.8kW per cubic meter pumped versus 4.5kW in comparable EU-made units.

Industry Implementation Casebook

Chilean Copper Mine: Replaced 18 centrifugal pumps with 12 Chinese vertical slurry units, achieving 31% energy reduction and 400-hour continuous operation capacity.

Indonesian Coal Plant: Custom high-head pumps increased ash disposal throughput by 2.7x while reducing seal replacements from monthly to biannually.

Next-Generation Slurry Pump Technology from China

Recent field tests of AI-enabled predictive maintenance systems show 89% accuracy in component failure forecasting. The integration of IoT sensors with 5G connectivity enables real-time viscosity adjustments, positioning Chinese manufacturers at the forefront of smart slurry pump innovation.

(bombas de escória na china)

FAQS on bombas de escória na china

Q: What are the advantages of using bombas de escória na china?

A: Bombas de escória na china are known for their durability, cost-effectiveness, and adaptability to harsh industrial environments. They are widely used in mining and metallurgy for efficient slag handling.

Q: How do bombas de escoria en china compare to global competitors?

A: Bombas de escoria en china often offer competitive pricing without compromising quality. Many manufacturers adhere to international standards, making them a reliable choice for global industries.

Q: Are bombas de lama na china suitable for high-density slurry transport?

A: Yes, bombas de lama na china are engineered to handle high-density slurries and abrasive materials. Advanced designs ensure minimal wear and extended operational lifespans.

Q: What industries commonly use bombas de escória na china?

A: These pumps are essential in mining, steel production, and power generation. They efficiently manage slag, waste, and byproducts in heavy-duty processes.

Q: Do Chinese manufacturers provide customized bombas de lama na china?

A: Many Chinese suppliers offer tailored solutions for bombas de lama na china, including custom flow rates, materials, and configurations to meet specific project requirements.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025