- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 02, 2025 02:09 Back to list

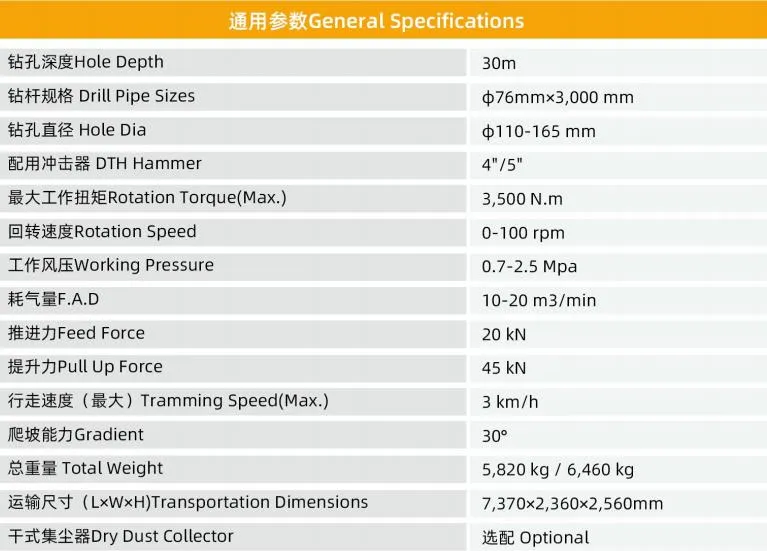

dth hammers and bits

Trusted sources in the industry often point to case studies to illustrate the benefits and improved outcomes by selecting suitable DTH equipment. For example, in a case where a company transitioned from a brand with frequent bit replacements to a premium-quality bit provider, they recorded a 25% reduction in operational downtime. This change not only increased productivity but also cut down significant costs associated with labor and equipment maintenance. Delving into the specifics of DTH hammers, the principle of functionality focuses on optimizing air consumption and delivering maximum impact energy. The latest models are designed with precise internal geometries to ensure minimal energy loss and robust performance in any ground conditions. From an authoritative standpoint, several leading manufacturers have set benchmarks in innovation, evolving the industry standards. These companies have invested in R&D, developing proprietary technologies intertwined with rigorous testing phases to ensure their hammers and bits are second to none. This ensures buyers are investing in trusted, tested, and true technologies. The choice of DTH hammers and bits significantly influences the direction of a drilling project. When one opts for proven products from reputed brands with extensive track records, one partners with reliability and ultimately mitigates risks associated with equipment failure. It is indispensable to engage with manufacturers or vendors that provide insights or simulation tests, showcasing tool performance under various conditions. In conclusion, while the selection process for DTH hammers and bits might seem daunting, drawing upon real-world experience, up-to-date expertise, and authoritative insights can simplify the decision-making process. Aligning these tools strategically with project-specific demands ensures efficiency and makes room for scalability in operations. This approach not only enhances trustworthiness and credibility in the field but also establishes a standard of excellence for any mining or drilling enterprise.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025