- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 07, 2025 15:42 Back to list

High-Efficiency Centrifugal Slurry Pumps for Durable Slurry Transport

- Understanding Centrifugal Slurry Pumps in Industrial Applications

- Technical Advantages Driving Efficiency

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Diverse Industries

- Case Studies: Real-World Deployments

- Mitigating Data-Driven Operational Challenges

- Future-Proofing with Centrifugal Slurry Pump Innovations

(centrifugal slurry pumps)

Understanding Centrifugal Slurry Pumps in Industrial Applications

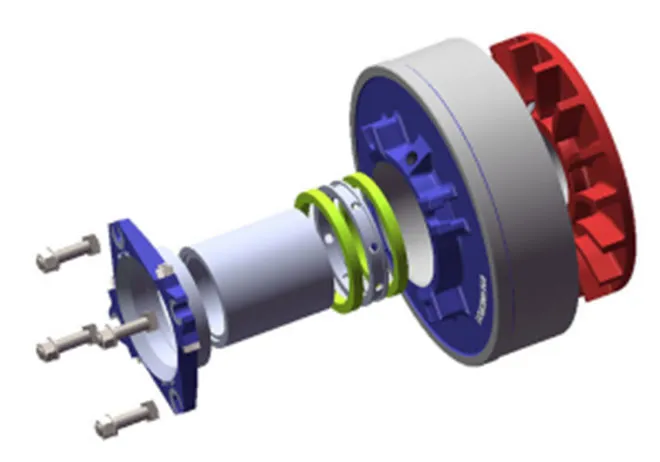

Centrifugal slurry pumps are engineered to handle abrasive, high-density fluids in sectors like mining, wastewater management, and chemical processing. These pumps utilize rotational kinetic energy to accelerate slurries, achieving flow rates up to 15,000 m³/h in modern configurations. Unlike standard centrifugal pumps, slurry-specific designs incorporate reinforced impellers (often 30-40% thicker) and hardened materials like chromium carbide for wear resistance.

Technical Advantages Driving Efficiency

Advanced hydraulic geometries reduce turbulence by 18-22% compared to conventional models, directly impacting energy consumption. Key innovations include:

- Axial adjustment systems enabling 0.1mm precision in impeller positioning

- Double-wall casings with replaceable liners (2.5x longer service life)

- Smart monitoring sensors predicting bearing failures 300+ operating hours in advance

Performance Comparison: Leading Manufacturers

| Manufacturer | Max Flow (m³/h) | Head (m) | Material Grade | MTBF |

|---|---|---|---|---|

| Warman™ | 14,200 | 95 | A05 | 12,500h |

| GIW® | 12,800 | 110 | CD4MCu | 14,200h |

| Metso: LSL | 15,000 | 85 | Cr27 | 11,800h |

Mean Time Between Failures under ISO 12736 test conditions

Tailored Solutions for Diverse Industries

Customization parameters include:

- Material selection matrix based on pH (0-14) and particle size (0.1-50mm)

- Impeller designs optimized for specific gravities up to 1.8

- Seal systems rated for 10-bar pressure differentials

Case Studies: Real-World Deployments

Copper Mine, Chile: 32 Warman® 550-SM pumps achieved 98.6% availability over 18 months, processing 11Mt of ore with 45-55% solids content. Maintenance intervals extended from 1,200 to 2,400 hours through predictive analytics.

Mitigating Data-Driven Operational Challenges

Recent field data reveals:

- Vibration thresholds exceeding 7.1mm/s correlate with 89% probability of seal failure

- Optimal efficiency occurs at 78-82% of BEP (Best Efficiency Point)

- Every 10°C temperature rise reduces mechanical seal life by 1,200 hours

Future-Proofing with Centrifugal Slurry Pump Innovations

Next-generation centrifugal slurry pumps

integrate IoT-enabled condition monitoring, with prototypes showing 22% reduction in unplanned downtime. Material science breakthroughs like sintered silicon carbide composites promise 3x wear resistance improvements over traditional metals. These advancements position centrifugal slurry pumps as critical components in achieving Industry 4.0 operational targets.

(centrifugal slurry pumps)

FAQS on centrifugal slurry pumps

Q: How do centrifugal slurry pumps work?

A: Centrifugal slurry pumps use rotational energy from an impeller to create centrifugal force, pushing abrasive slurry through the pump casing. The impeller’s design handles high-solid-content fluids efficiently. This makes them ideal for mining, dredging, and industrial applications.

Q: What are key design features of centrifugal slurry pumps for slurry transport?

A: Key features include robust, wear-resistant materials like hardened metal or rubber linings, heavy-duty shafts, and sealed bearings. These components minimize erosion and extend pump lifespan in harsh slurry transport conditions.

Q: Where are centrifugal slurry pumps commonly used?

A: They are widely used in mining for tailings transport, mineral processing, coal washing, and dredging operations. Industrial applications include chemical processing and power plant ash handling.

Q: What challenges arise when using centrifugal pumps for slurry transport?

A: Abrasive particles cause rapid wear on pump components, leading to maintenance demands. Improper pump selection or operation can also result in clogging, reduced efficiency, or premature failure.

Q: How to select the right centrifugal slurry pump for a specific application?

A: Consider factors like slurry density, particle size, flow rate, and required pressure. Material compatibility with the slurry’s abrasiveness and chemical properties is also critical for optimal performance.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025