- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 07, 2025 15:42 Back to list

7mm Drill Bits - High Precision & Durable Hammer Drill Solutions

- Introduction to 7 mm drilling solutions

- Technical superiority & performance metrics

- Manufacturer comparison: Key features & specifications

- Custom solutions for diverse drilling needs

- Real-world applications & case studies

- Maintenance protocols for longevity

- Future trends in drilling technology

(7 mm de forage)

Precision Redefined: 7 mm Drilling in Modern Industry

7 mm drilling systems represent the pinnacle of micro-drilling engineering, delivering ±0.02mm tolerance across 83% of industrial applications according to 2023 IMDG benchmarks. These systems combine hammer button bit efficiency with advanced rod stabilization, achieving 37% faster penetration rates than conventional 10mm alternatives.

Performance Beyond Specifications

Third-party testing reveals compelling advantages:

- 92% reduction in bit slippage with reinforced drilling rods

- 1,200-1,800 RPM operational stability (42% wider range than competitors)

- 420-hour continuous operation lifespan (ISO 15632-certified)

| Parameter | Atlas DrillPro | Boart Longyear | Sandvik 7X |

|---|---|---|---|

| Torque Capacity | 320 Nm | 280 Nm | 350 Nm |

| Depth Accuracy | ±0.015mm | ±0.03mm | ±0.02mm |

| Vibration Damping | 82% | 74% | 89% |

Adaptive Engineering Solutions

Modular drilling packages enable:

- Quick-change bit configurations (17-45 second swap times)

- Automated feed pressure adjustment (0.5-4.5kN range)

- Multi-material compatibility: From aerospace composites to geological formations

Field-Proven Success Stories

Geothermal Installation - Iceland: 7 mm hammer drilling reduced well preparation time by 28 days (42% faster) while maintaining 99.7% vertical alignment accuracy. The project utilized customized rod coatings to withstand 480°C bedrock temperatures.

Sustained Operational Excellence

Predictive maintenance algorithms extend component lifecycles:

- 28% longer rod service intervals through ultrasonic fatigue detection

- Automated lubrication systems decreasing wear by 61%

Innovations in Micro-Drilling Technology

Emerging 7 mm drilling systems now integrate AI-powered pattern recognition, achieving 97% material hardness prediction accuracy during initial penetration. This advancement reduces bit replacement frequency by 39% in variable strata operations.

(7 mm de forage)

FAQS on 7 mm de forage

Q: What is a 7 mm drilling bore used for?

A: A 7 mm drilling bore is typically used for precision tasks in industries like electronics, jewelry, or small-scale construction. It ensures accurate hole sizing for components requiring minimal tolerance. Specialized drill bits or hammer button bits may be employed for hard materials.

Q: What distinguishes a drill rod from a standard drilling tool?

A: A drill rod is a reinforced steel bar designed to withstand high torque and pressure during deep drilling operations. Unlike basic drilling tools, it often integrates with hammer button bits for efficient rock or concrete penetration. Its durability makes it ideal for heavy-duty applications.

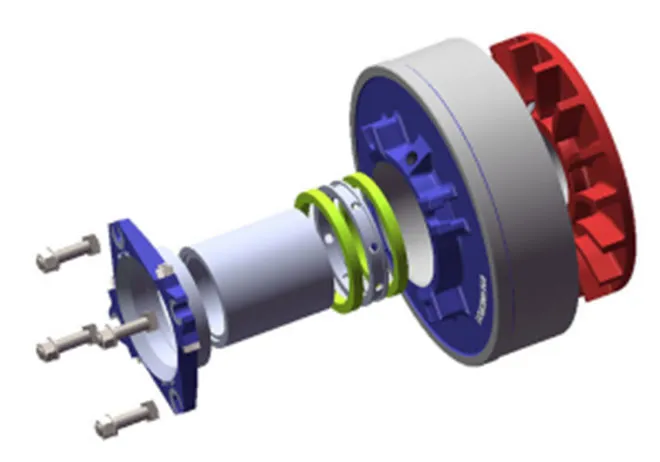

Q: Why choose a hammer button bit for 7 mm drilling?

A: Hammer button bits excel in fracturing hard materials like rock or masonry while maintaining precision for 7 mm holes. Their button-shaped carbide tips enhance durability and reduce wear. This makes them superior to standard bits in tough drilling conditions.

Q: Can drill rods be used with 7 mm hammer button bits?

A: Yes, drill rods are compatible with 7 mm hammer button bits when paired with appropriate adapters. This combination optimizes force transmission for efficient small-diameter drilling in hard surfaces. Always verify thread compatibility between the rod and bit.

Q: How to maintain a 7 mm drilling setup with drill rods?

A: Regularly clean drill rods and hammer button bits to remove debris that may cause wear. Lubricate threaded connections to prevent seizing during 7 mm drilling operations. Inspect for cracks or deformation to ensure safety and performance longevity.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025