- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 14, 2025 15:22 Back to list

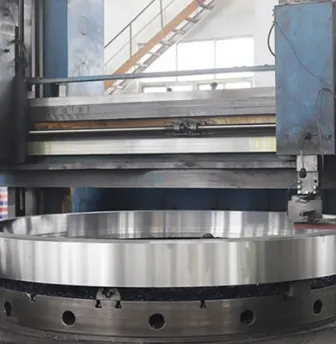

Optimizing Crusher Performance with Quality Bearings

The performance and longevity of crushers—whether bearing jaw crushers, cone crusher thrust bearings, or replacement parts—are heavily dependent on the quality and maintenance of the bearings used. Crushers operate in demanding environments where precision, durability, and reliability are essential. To maintain efficient operation and extend the lifespan of equipment, investing in high-quality bearings and performing timely jaw crusher bearing replacements are critical. This advertorial will dive into the importance of bearing jaw crushers, understanding cone crusher thrust bearings, and the need for effective jaw crusher bearing replacements.

Bearing Jaw Crushers: Enhancing Crusher Efficiency

Bearing jaw crushers are integral to the performance of the machine. They help support the heavy load placed on the jaw during crushing operations. These crushers work by utilizing the strength of their bearings, which bear the pressure generated as rocks and other materials are crushed. The bearing jaw crusher needs to be precisely engineered to handle the significant forces exerted during operation.

The quality of the bearings used in jaw crushers affects the machine’s efficiency, stability, and long-term performance. Properly designed and maintained bearing jaw crushers will have longer service lives and fewer mechanical issues. A failure in the bearings can cause misalignment, increased friction, and ultimately, unplanned downtime—costing time and resources. As such, choosing durable and high-performance bearing jaw crushers can significantly enhance overall crushing productivity.

Cone Crusher Thrust Bearings: Vital Components for Stability

A crucial part of any cone crusher is the cone crusher thrust bearing, which ensures the alignment and rotational stability of the cone. These bearings are designed to handle the axial load of the cone, providing the necessary support during operation. The cone crusher thrust bearing plays a pivotal role in enabling smooth and efficient movement of the cone.

For any cone crusher to perform optimally, it requires a thrust bearing that can withstand high pressures and rotational speeds. Choosing the right cone crusher thrust bearing is essential for ensuring that the crusher functions efficiently under varying loads and operating conditions. Poor-quality bearings can lead to premature failure, resulting in costly repairs and unscheduled downtime. Upgrading to high-quality cone crusher thrust bearings ensures reliability and continuous performance, ultimately boosting production and reducing maintenance costs.

Jaw Crusher Bearing Replacement: Keeping Crushers Running

Over time, wear and tear can cause a decrease in the performance of jaw crushers, especially concerning their bearings. When bearings show signs of damage, jaw crusher bearing replacements become necessary to restore the machine’s functionality. Replacing the bearings on time can help prevent more severe issues, such as complete bearing failure, which can cause significant damage to other components of the crusher.

Jaw crusher bearing replacement involves removing old or worn-out bearings and installing new ones to maintain the machine’s efficiency and prolong its lifespan. Timely replacement ensures the crusher operates smoothly, reducing friction and preventing unnecessary strain on other parts. Regular inspection and jaw crusher bearing replacement are vital steps in maintaining crusher performance, especially for machines operating in tough conditions where wear and tear are inevitable. High-quality replacement bearings ensure seamless integration into the crusher and extend operational periods between overhauls.

Jaw Crusher Bearing Replacement: An Essential Preventive Measure

Preventive maintenance and timely jaw crusher bearing replacement play an essential role in ensuring that crushers continue to perform at their peak efficiency. Bearings are one of the most common components to fail in jaw crushers, and early detection of wear can save companies significant downtime and repair costs. Preventing a total bearing failure through early jaw crusher bearing replacement can avoid the complete shutdown of the crusher, which could result in missed production deadlines.

Investing in high-quality replacement bearings can prevent frequent repairs and reduce the overall costs associated with maintaining jaw crushers. An effective bearing replacement strategy involves understanding the signs of wear, including unusual noises, excessive heat, or inconsistent operation, which are often indicators that a bearing needs to be replaced. By keeping an eye on the condition of the bearings and replacing them promptly, crusher owners can avoid costly repairs, maximize equipment lifespan, and ensure consistent performance.

Invest in Quality Bearings for Long-Term Crusher Efficiency

The key to maximizing the efficiency and longevity of crushers lies in investing in high-quality bearing jaw crushers, cone crusher thrust bearings, and performing timely jaw crusher bearing replacements. The importance of maintaining and replacing bearings cannot be overstated, as they are the backbone of the crusher’s functionality. Proper bearing selection, maintenance, and timely replacement can help avoid operational disruptions and enhance the overall performance of the equipment.

Regular inspection and use of premium-quality bearings ensure that crushers operate at their best, reducing downtime, improving production, and lowering maintenance costs. When choosing bearing jaw crushers, cone crusher thrust bearings, or planning a jaw crusher bearing replacement, partnering with reliable suppliers who provide durable and high-performance bearings is essential. A well-maintained crusher with quality bearings will undoubtedly lead to long-term operational success and higher efficiency.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025