- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 02, 2025 05:19 Back to list

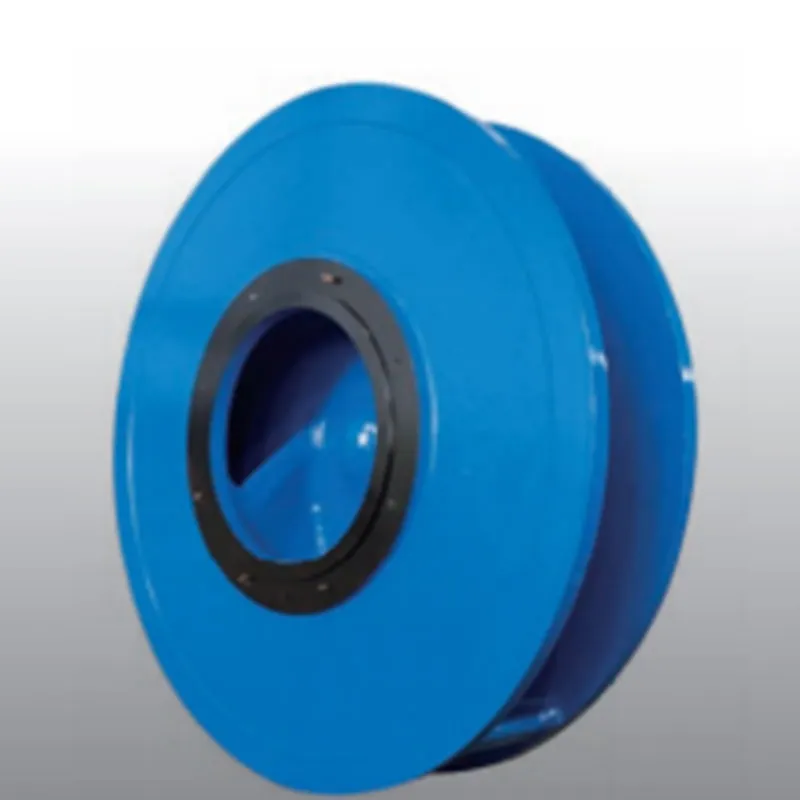

bullet teeth

Trustworthy brands have emerged within the bullet teeth industry by consistently providing reliable, high-performance products. These companies invest heavily in research and development to innovate and improve their product lines continually. A reputable brand offers a variety of bullet tooth options tailored for different applications, allowing operators to select products confidently. Customers often rely on these trusted names for their proven track record in enhancing machine efficiency and reducing long-term operational costs. When assessing bullet teeth from a professional standpoint, it is crucial to consider feedback from established users and sector-specific experts. Their firsthand experience and insights into product performance in various conditions can guide new users toward making informed choices. Forums and reviews often serve as valuable resources for prospective buyers, offering a glimpse into real-world performance and customer satisfaction. To sum up, the effective use of bullet teeth in industrial machinery involves more than just selecting a product off the shelf. It requires a detailed understanding of the task at hand, an assessment of the operating conditions, and an informed choice of materials and design. Listening to the seasoned professionals who have decades of experience with these components, one can gain insights into maximizing efficiency and cutting costs. As technology advances, so too does the capability and variety of bullet teeth available, making it all the more crucial to stay informed and make expert-backed decisions. In essence, bullet teeth are not merely components but are central to the operational success of machinery across various industries. The expertise required to choose and maintain these tools, combined with the reliability afforded by established manufacturers, equips operators with improved performance and outcome reliability. Therefore, understanding and investing in the right bullet teeth is indispensable for any industry professional looking to optimize their operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025