- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 06, 2025 01:52 Back to list

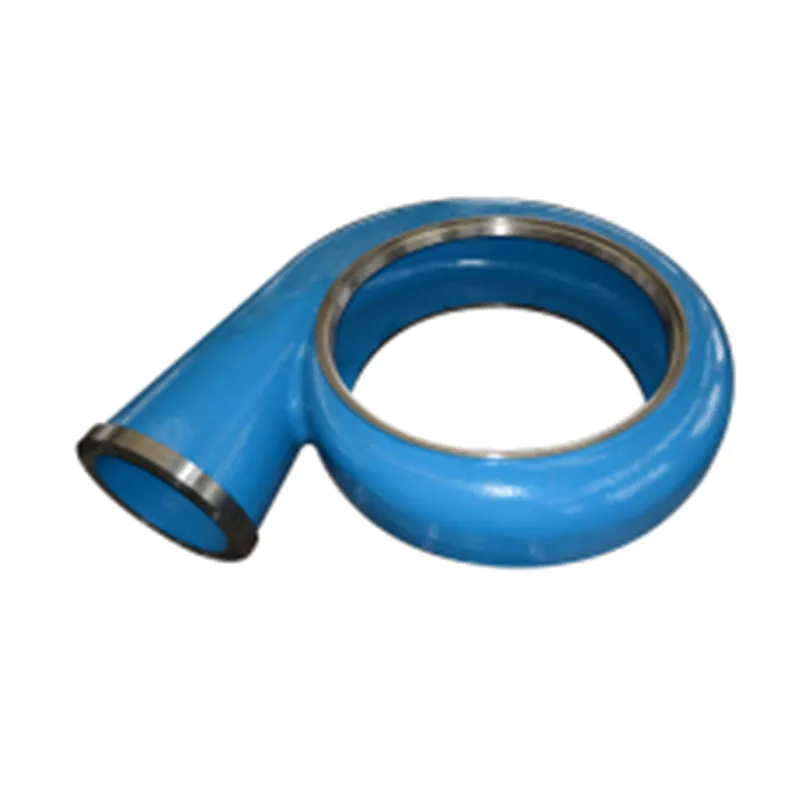

wholesale slurry pump spare parts

Part of ensuring trustworthiness involves verifying the provenance of the parts. Are they genuine OEM products or high-quality aftermarket alternatives? While aftermarket parts can offer cost advantages, it's essential to ensure they meet or exceed OEM specifications to avoid any compromise on performance or safety. Guaranteeing the authenticity of parts prevents future operational issues and maintains the integrity of your machinery. The selection process should also involve a thorough understanding of the environmental and operational conditions in which your pumps function. Different materials, coatings, and designs may be more suitable depending on the level of abrasion, corrosion, and temperature your slurry pumps are exposed to. For example, parts made from hardened alloys or with specialized coatings can significantly extend the lifespan of the pump when operating in particularly abrasive environments. Moreover, it is advantageous to engage with suppliers offering robust inventory management systems. As the exact timing for part replacements can be unpredictable, having a supplier with a reliable inventory management system ensures swift accessibility to critical parts. This minimizes downtime and keeps operations running smoothly, even in the event of unexpected part failure. Lastly, consider the long-term relationship potential with your supplier. Establishing a strong partnership benefits both parties, as it often leads to exclusive insights into the latest industry innovations and participation in beta testing new products that could offer even greater efficiency and performance. In conclusion, buying wholesale slurry pump spare parts is a strategic process that requires careful consideration of quality, supplier expertise, authenticity, and operational needs. By focusing on these aspects, businesses can ensure that their slurry pumps work efficiently and reliably, supporting the overarching goal of minimizing downtime and enhancing long-term productivity. Working with a knowledgeable and reputable supplier can make a significant difference, not only in the quality of the parts acquired but in the overall success of the maintenance strategy.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025