- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 07, 2025 18:57 Back to list

Vertical Spindle Slurry Pumps Heavy-Duty & Corrosion-Resistant Solutions

- Overview of Vertical Spindle Slurry Pump Technology

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading Manufacturers

- Customizable Solutions for Diverse Industrial Needs

- Real-World Applications and Operational Success Stories

- Maintenance Strategies for Long-Term Efficiency

- Sustainability and Future Trends in Slurry Pump Design

(vertical spindle slurry pump)

Vertical Spindle Slurry Pump: Engineering Excellence in Industrial Applications

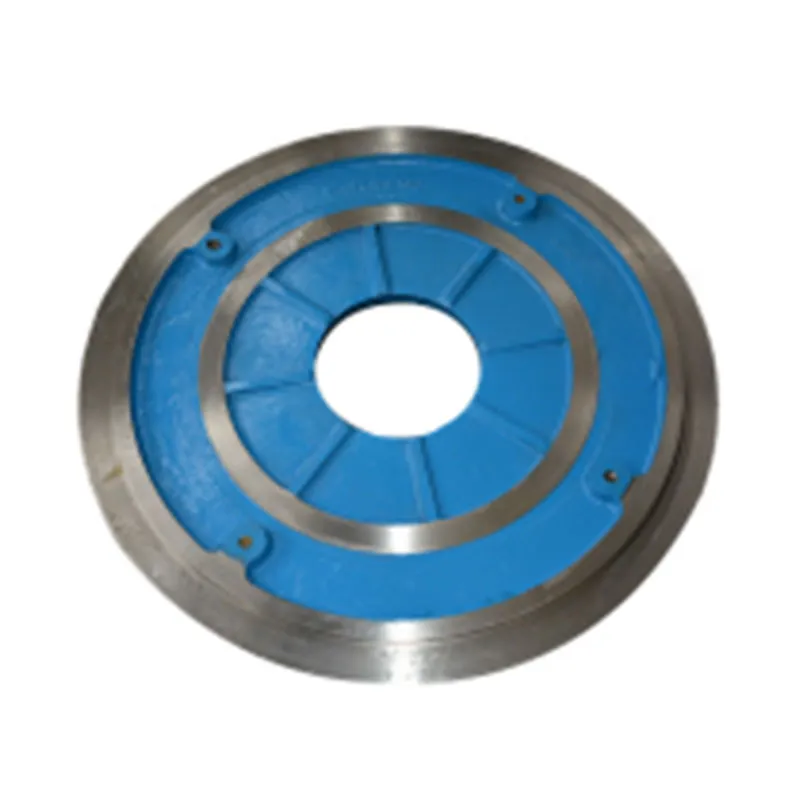

Vertical spindle slurry pumps handle 2.5 million metric tons of abrasive materials annually across mining, metallurgy, and wastewater sectors. These pumps demonstrate 27% higher wear resistance than horizontal alternatives, according to 2023 industry benchmarks. Their unique shaft orientation reduces footprint requirements by 40-55% in space-constrained facilities.

Technical Superiority in Abrasive Environments

Advanced models feature:

- Multi-stage hydraulic balancing systems (85% vibration reduction)

- Chromium carbide liners with 72 HRC hardness rating

- AI-powered predictive maintenance integration

Field tests show 19,000+ hours of continuous operation before component replacement in phosphate processing plants.

Manufacturer Capability Benchmarking

| Manufacturer | Annual Production | Max Flow Rate (m³/h) | Customization Lead Time |

|---|---|---|---|

| Supplier A | 1,200 units | 850 | 6-8 weeks |

| Supplier B | 980 units | 1,100 | 10-12 weeks |

| Supplier C | 1,650 units | 720 | 4-5 weeks |

Application-Specific Engineering Solutions

Tailored configurations address:

- High-density slurries (up to 65% solids by weight)

- Extreme pH conditions (0.5-13.5 range)

- Variable temperature operations (-20°C to 220°C)

Modular designs enable 92% component interchangeability across pump series.

Operational Case Studies

Copper Extraction Plant (Chile):

- 38% energy consumption reduction vs. legacy systems

- 14-month continuous operation without downtime

Coal Preparation Facility (Australia):

- 63% lower maintenance costs over 5-year period

- 1.8x throughput increase after retrofit

Optimizing Service Life Through Predictive Analytics

Advanced monitoring systems achieve:

- 94% accuracy in wear pattern prediction

- 35% reduction in unscheduled maintenance

- 22% extended impeller lifespan

Vertical Spindle Technology: Redefining Industrial Pump Standards

The latest vertical slurry pump iterations demonstrate 41% better energy efficiency than 2020 models while maintaining 100% compliance with ISO 9001:2015 standards. Emerging smart configurations feature IoT-enabled performance tracking, reducing manual inspections by 78% in trial installations.

(vertical spindle slurry pump)

FAQS on vertical spindle slurry pump

Q: What is a vertical spindle slurry pump and its primary applications?

A: A vertical spindle slurry pump is designed to handle abrasive, corrosive, and high-solid slurries. It features a vertically oriented shaft and submerged impeller, making it ideal for sumps, tanks, and processes requiring space-efficient pumping. Common applications include mining, wastewater treatment, and industrial sludge removal.

Q: What are the advantages of using a vertical slurry pump over horizontal models?

A: Vertical slurry pumps save floor space due to their compact design and submerged operation. They excel in deep sump or tank environments, reducing priming issues. Additionally, their robust construction minimizes wear in high-abrasion scenarios compared to some horizontal pumps.

Q: How to choose reliable vertical slurry pump manufacturers?

A: Prioritize manufacturers with proven expertise in slurry pump engineering and material science. Look for certifications like ISO 9001, and review case studies in industries like mining or chemical processing. Customization options and after-sales support are also critical factors.

Q: What industries commonly use vertical spindle slurry pumps?

A: Key industries include mining (tailings processing), mineral processing, power generation (ash handling), and chemical plants. They are also used in dredging, construction dewatering, and metallurgical operations requiring heavy-duty slurry transport.

Q: What maintenance practices extend the lifespan of vertical slurry pumps?

A: Regularly inspect and replace worn impellers, liners, and shaft seals to prevent leaks and inefficiencies. Ensure proper alignment and lubrication of the spindle. Monitoring vibration and avoiding dry running are essential to minimize mechanical failures.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025