- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Mar . 06, 2025 15:54 Back to list

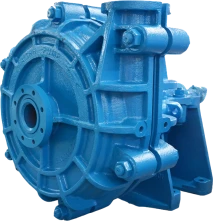

Impeller

Authoritative guidelines from industry leaders, like the American Petroleum Institute (API), provide substantial support in selecting appropriate mud pump seals. Adhering to API standards ensures that the seals meet the necessary safety and performance requirements. Moreover, collaborations with reputable manufacturers who have a track record of innovation and reliability in seal technology further solidify trust in the product's performance. Trustworthiness, especially in the context of mud pump operations, is fostered through establishing robust maintenance and inspection routines for the seals. Regularly scheduled inspections can preemptively identify wear and potential failures, thereby averting unexpected breakdowns. Additionally, implementing a proactive replacement strategy ensures that seals are always in optimal condition, reducing the risk of operational mishaps. The advancement of technology in seal design brings further gains in operational efficiency and reliability. Innovations such as self-adjusting seals, designed to adapt to varying pressure and temperature conditions, offer exciting prospects in the industry. These dynamic seals can significantly extend the operational life of mud pumps by minimizing wear and ensuring a consistently optimal seal. In conclusion, the significance of mud pump seals in maintaining operational integrity cannot be overstated. Drawing from real-world experiences, leveraging technical expertise, following authoritative guidelines, and fostering trust through maintenance and innovation ensures these components function flawlessly. This holistic approach not only enhances the performance of mud pumps but also contributes to the ongoing success and safety of operations within high-stake industries. Proper attention to sealing technology thus remains a critical focus for engineers and managers committed to excellence in heavy-duty machinery performance.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025