- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 12, 2025 01:23 Back to list

rock auger bullet teeth

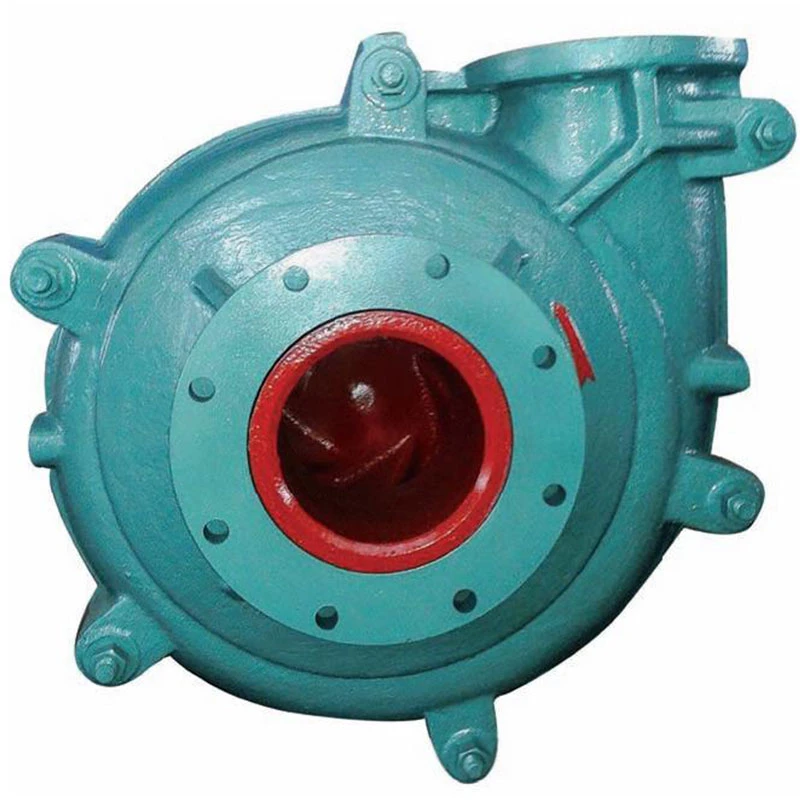

Professional expertise is essential when selecting and operating centrifugal pumps for sludge transport. Factors such as pump size, capacity, head, and power consumption must be considered to match the specific requirements of the application. The correct pump selection can influence the efficiency and longevity of the pumping system. Consulting with industry experts and leveraging modern computational fluid dynamics tools can optimize pump performance, saving energy and reducing costs. Authoritativeness in the field is demonstrated by understanding the environmental impact and regulatory requirements surrounding sludge management. Properly engineered centrifugal pumping systems not only comply with regulations but also contribute to environmental sustainability. Advanced designs and materials used in the construction of centrifugal pumps can resist corrosive elements present in sludge, ensuring that environmental protection standards are upheld. Trustworthiness in recommending centrifugal pumps comes from delivering solutions that are backed by proven industry standards and positive client testimonials. Companies that integrate centrifugal pumps into their operations frequently report increased efficiency, reduced downtime, and significant cost savings. These results are indicative of the centrifugal pump’s reliability in handling challenging industrial sludge applications. In conclusion, utilizing a centrifugal pump to transport sludge is a strategic decision that combines efficiency, expertise, and environmental responsibility. Industries seeking to improve their sludge handling processes should consider the centrifugal pump’s unparalleled capabilities. With a focus on experience, professional insight, authority in the field, and reliability, centrifugal pumps offer a superior solution to the demands of modern sludge transportation challenges.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025