- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Apr . 07, 2025 09:43 Back to list

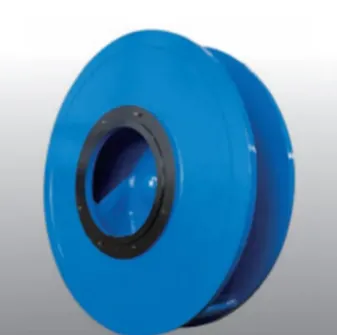

The Ultimate Guide to Slurry Pump Impellers and Their Importance

In industries dealing with high-density liquids and slurry, the slurry pump is a crucial piece of equipment. Central to the performance and efficiency of slurry pumps is the slurry pump impeller. In this guide, we will explore the critical role of wholesale slurry pump impeller, the different types of slurry pump impeller manufacturers, and key considerations like the slurry pump impeller material and design. Understanding these factors can significantly impact the effectiveness and longevity of slurry pumps used in mining, wastewater treatment, and other heavy-duty applications.

Wholesale Slurry Pump Impeller: Affordable Solutions for Industrial Needs

When managing large-scale industrial operations, particularly those involving slurry pumping systems, the cost-effectiveness of spare parts like the wholesale slurry pump impeller becomes critical. Purchasing wholesale slurry pump impeller options ensures that businesses can maintain their equipment without breaking the bank. Bulk purchasing these essential components from trusted suppliers also reduces operational downtime, ensuring that pumps continue to run smoothly even in challenging environments.

The benefit of sourcing wholesale slurry pump impellers lies not just in cost savings, but in the ability to stock up on high-quality, durable impellers that are suited for continuous, heavy-duty applications. Whether you need a replacement or additional parts to keep your operation running, wholesale slurry pump impellers offer the reliability and quality required for demanding industries.

In addition to cost benefits, wholesale slurry pump impellers can also be customized for various operational needs. These impellers are available in a wide range of sizes and specifications, ensuring that the right match is made for every slurry pump application. A wide selection also allows companies to have spares readily available, preventing delays caused by ordering and shipping individual parts.

Slurry Pump Impeller Manufacturers: The Key to Quality and Durability

Choosing the right slurry pump impeller manufacturers is essential for the performance and reliability of your slurry pumps. These manufacturers are responsible for producing impellers that meet high standards of quality and durability, ensuring they can handle abrasive and corrosive materials commonly found in slurry mixtures.

Slurry pump impeller manufacturers use advanced techniques and materials to produce impellers that deliver optimal performance. With years of industry experience, these manufacturers understand the demands of various applications and design impellers that maximize pumping efficiency and reduce wear.

The best slurry pump impeller manufacturers employ strict quality control measures during the production process to guarantee that each impeller will perform optimally in even the toughest conditions. They also offer various custom options to suit the specific requirements of different industries, such as mining, construction, and wastewater treatment. Working with trusted manufacturers ensures that your slurry pump impellers meet high standards for strength, resistance, and longevity.

Sludge Pump Impeller: Specialized Design for Tough Environments

The sludge pump impeller is a specialized component designed for handling sludge, which often contains more solid particles and requires more robust engineering than typical slurry mixtures. Unlike other pumps, sludge pump impellers are built to handle thicker, more viscous materials without losing efficiency.

Manufacturers of sludge pump impellers use heavy-duty materials that can withstand the pressure and abrasive wear caused by the continuous circulation of thick sludge. Whether in wastewater treatment facilities, sewage systems, or industrial applications, the sludge pump impeller ensures that thick, difficult-to-pump materials are moved with minimal energy loss.

The unique construction of sludge pump impellers includes a focus on durability and reliability, as these impellers are often exposed to harsh conditions that could cause premature failure. Understanding the specific requirements for your pumping operation can help you select the most suitable sludge pump impeller for your needs.

Slurry Pump Impeller Factory: Mass Production with Precision

The slurry pump impeller factory is where the manufacturing process comes to life. These factories use state-of-the-art technologies and machinery to mass-produce slurry pump impellers that are engineered to deliver maximum performance. The factories work with high-grade materials and employ experienced technicians to ensure that each impeller meets the required specifications.

A reputable slurry pump impeller factory ensures that each impeller is produced with precision, ensuring that the design and construction meet industry standards for durability, performance, and efficiency. These factories can also provide custom designs to cater to specific pumping needs, ensuring that each impeller is suited for the environment in which it will be used.

In addition to producing high-quality impellers, slurry pump impeller factories offer valuable services such as quality checks and testing to confirm the functionality of each part before delivery. This guarantees that only the best impellers reach the customers and minimizes the risk of defects or failures in the field.

Slurry Pump Impeller Material: The Right Choice for Longevity and Performance

The slurry pump impeller material is one of the most critical factors influencing the performance and durability of the impeller. The right materials can greatly extend the lifespan of slurry pumps by minimizing wear and corrosion, especially when handling abrasive or chemically reactive slurries.

Common slurry pump impeller materials include high-chrome iron, stainless steel, and rubber-lined castings, each selected based on the specific needs of the pumping application. High-chrome iron is particularly effective for highly abrasive slurries, while stainless steel is more resistant to corrosion. Rubber-lined impellers are ideal for slurries containing chemicals or for applications where flexibility is key.

Choosing the correct slurry pump impeller material depends on factors like the type of slurry being pumped, the flow conditions, and the environmental factors involved. For example, when pumping sand or gravel, a high-chrome iron impeller may be necessary to resist wear. On the other hand, for acidic or corrosive liquids, stainless steel or rubber-lined impellers offer superior protection against degradation.

The slurry pump impeller design plays a significant role in the efficiency and performance of the pump. The design of the impeller determines how efficiently it can move slurry through the system, as well as how well it can resist wear and tear. Manufacturers use advanced design tools and computational fluid dynamics to create impellers that optimize both performance and energy efficiency.

There are several designs of slurry pump impellers, each suited for specific applications. Open impellers, semi-open impellers, and closed impellers are the most common types, each with distinct advantages. Open impellers are suitable for slurries with large particles, while closed impellers provide more efficient pumping in cleaner slurries. Semi-open impellers offer a balance between the two and are often used in more versatile applications.

Custom slurry pump impeller designs are often required for specialized applications, where standard designs may not perform adequately. The ability to customize the slurry pump impeller design allows businesses to ensure that their pumps operate at optimal efficiency, saving both energy and operational costs.

Choosing the right slurry pump impeller is critical for ensuring the efficiency, reliability, and longevity of slurry pumps used in industrial applications. From wholesale slurry pump impellers to the importance of selecting the right slurry pump impeller manufacturers, every factor influences the performance of your equipment. Understanding the role of the slurry pump impeller material, design, and manufacturing process ensures that your slurry pump will operate effectively in even the most demanding environments.

By sourcing impellers from reputable manufacturers, considering the material and design that best suits your needs, and leveraging the benefits of bulk purchasing, you can keep your slurry pumps running smoothly, reducing downtime and maintenance costs. Ultimately, selecting the best impeller for your slurry pump is key to ensuring the long-term performance and cost-effectiveness of your operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025