- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 15, 2025 04:52 Back to list

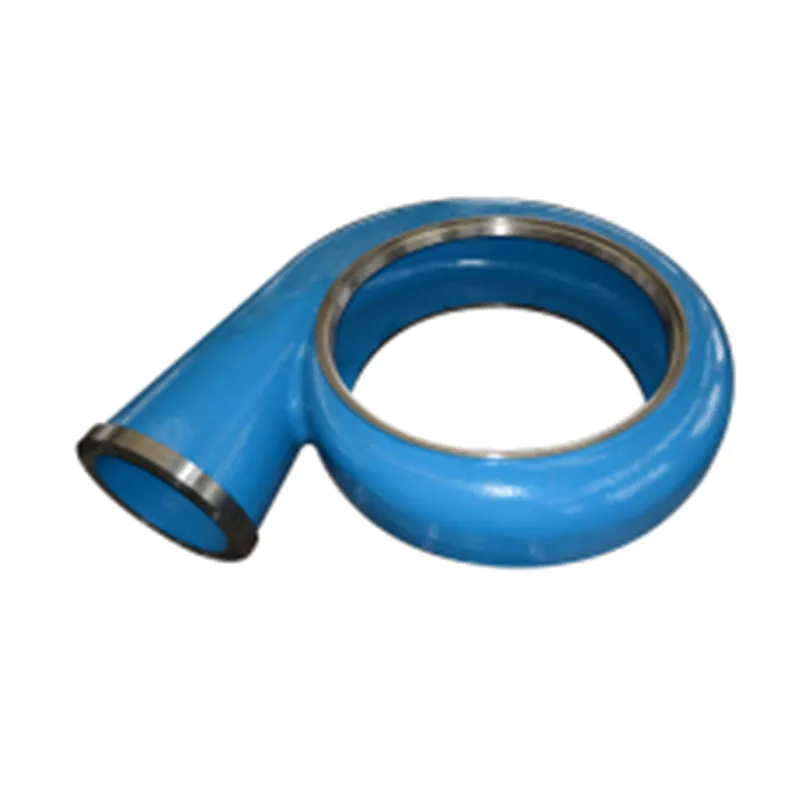

stone crusher parts

Authoritativeness in the stone crusher parts industry springs from innovation and adherence to international standards. Top manufacturers are often involved in continuous research and development, pushing the boundaries of what's possible with material technology and design improvements. They hold certifications from recognized bodies, ensuring their products meet global safety and performance benchmarks. This dedication to quality not only reassures existing clients but positions them as leaders in the market. Trustworthiness emerges from a manufacturer's track record and commitment to customer success. Companies that invest in post-purchase support, offering services such as installation, maintenance visits, and troubleshooting, cultivate a reputation for reliability and trust. Open channels of communication for feedback and innovation requests further solidify this trust, turning customers into long-term partners. The future of stone crusher parts lies in smart technology integration, where sensors and IoT capabilities can usher in a new era of predictive maintenance and real-time performance monitoring. This technological evolution promises to minimize downtime and optimize resource usage, embodying the next phase in customer-centric solutions within the industry. Conclusively, stone crusher parts are more than mere mechanical components; they are pivotal in ensuring the efficiency and sustainability of stone crushing operations. By focusing on experience, expertise, authoritativeness, and trustworthiness, manufacturers can continue to elevate the standards and meet the ever-evolving needs of the industry, driving innovation and efficiency with every component.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025