- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 09, 2025 14:08 Back to list

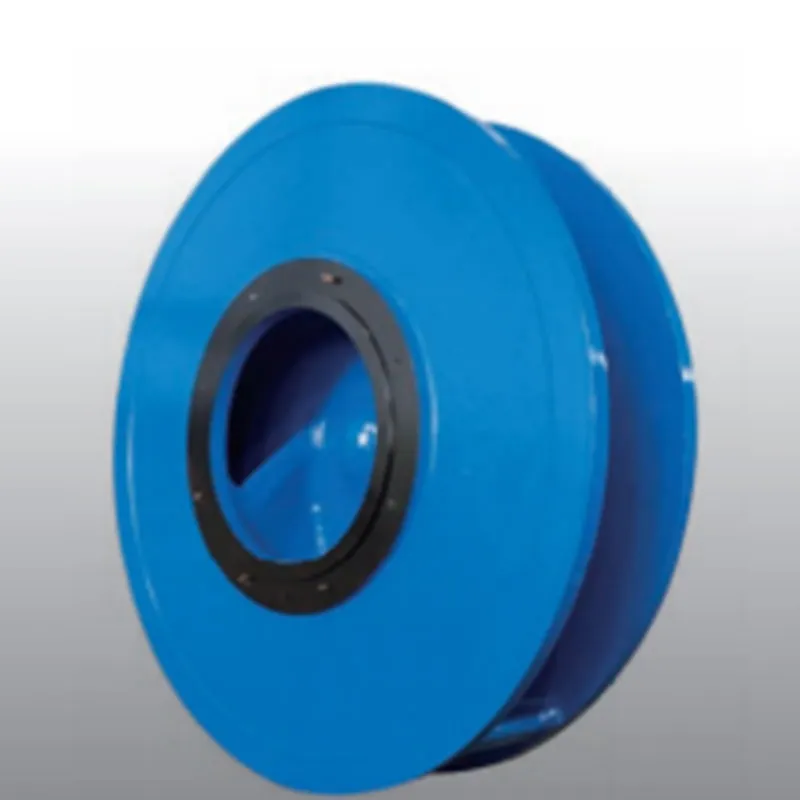

slurry pump factory

Environmental considerations have become ever more critical in recent years. Leading slurry pump factories are increasingly adopting sustainable manufacturing practices—such as reducing energy consumption, utilizing eco-friendly materials, and implementing waste recycling methods. Such conscientious practices not only aid in environmental conservation but also resonate with companies aiming to lower their carbon footprint, aligning their procurement strategies with green initiatives. For professionals in industries that rely heavily on slurry pumps, the selection of a factory should be influenced by these core attributes—experience, expertise, authoritativeness, and trustworthiness. An informed choice ensures that the pumps integrated into their operations are robust, efficient, and sustainable. The right factory not only supplies equipment but also acts as a partner in technological advancement and ecological stewardship. In conclusion, by prioritizing these factors, industries can safeguard their processes against inefficiencies and downtime, maintain compliance with environmental benchmarks, and contribute to the overarching goal of sustainable industrial growth, establishing a resilient and responsible production ecosystem.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025