- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 13, 2025 18:30 Back to list

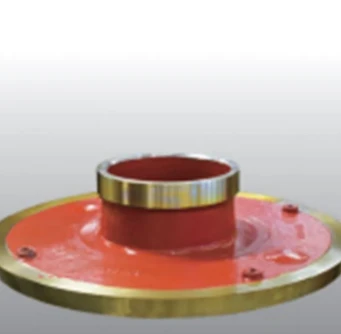

ZGB (P) Series Grout Pump

Authoritativeness is further demonstrated by the industry-wide adoption of advanced computerized design technologies in crafting crusher liners. The use of sophisticated CAD software allows engineers to simulate the crushing process, optimize liner geometry, and consequently improve both energy consumption and throughput. A trusted authority in engineering solutions, TechCrush Innovations, advocates for the integration of computational fluid dynamics in the design phase. They claim that such innovation has resulted in a 12% increase in throughput rate while reducing energy requirements, substantiating their leadership status in the industry. Trustworthiness can be illustrated by consistent product testing and adherence to industry standards and protocols. Before reaching the market, each batch of conical crusher liners undergoes rigorous testing to ensure compliance with ISO and ASTM standards. Such dedication to quality not only strengthens a product’s reputation but also fosters trust within industry circles, ensuring that companies relying on these liners operate smoothly with minimized risk of catastrophic equipment failure. In sum, the conical crusher liner stands as a critical component for industries dependent on efficient material processing. Its design and manufacture reflect a commitment to excellence and constant innovation. By focusing on high-quality materials, expert design insights, and an ongoing dedication to achieving pinnacle operational standards, manufacturers can present their product as a reliable powerhouse capable of enduring the rigors of heavy-duty applications. As evolving technological tools continue to redefine traditional methods, the future of conical crusher liners promises even greater advancements in operational efficiency and product longevity.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025