- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 18, 2025 10:38 Back to list

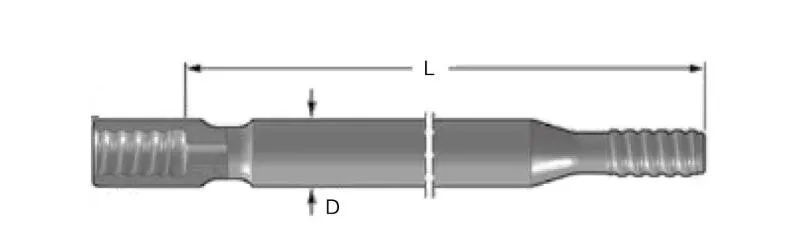

Decompression Cover, Stuffing Box

When considering newer suppliers or those less established, assessing their innovation capacity becomes essential. Some emerging suppliers may offer cutting-edge technology or innovative materials that could enhance mud pump performance. Innovation should not come at the expense of proven reliability, so such advancements should be backed by rigorous testing and validation. The comprehensive assessment should also include examining the supplier's logistical capabilities. Efficient delivery systems are vital, especially in remote drilling locations where a delay can spiral into costly downtimes. Suppliers with global supply chain infrastructure and partnerships tend to deliver faster and more efficiently. Finally, customer support is undeniably vital. Responsive, knowledgeable customer service teams ensure that challenges and queries are addressed promptly. This aspect of service provision is critical; seamless communication can tremendously influence operational success when urgent issues arise. In summary, selecting the ideal mud pump parts supplier involves a careful balance of experience, expertise, authoritativeness, and trustworthiness. Companies need to conduct thorough research, leveraging industry connections, and scrutinizing potential suppliers’ credentials to ensure they align with operational needs and business objectives. By prioritizing these factors, businesses can ensure they maintain efficient and uninterrupted operations, significantly contributing to overall success in the highly competitive oil and gas market.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025