- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jul . 08, 2025 04:20 Back to list

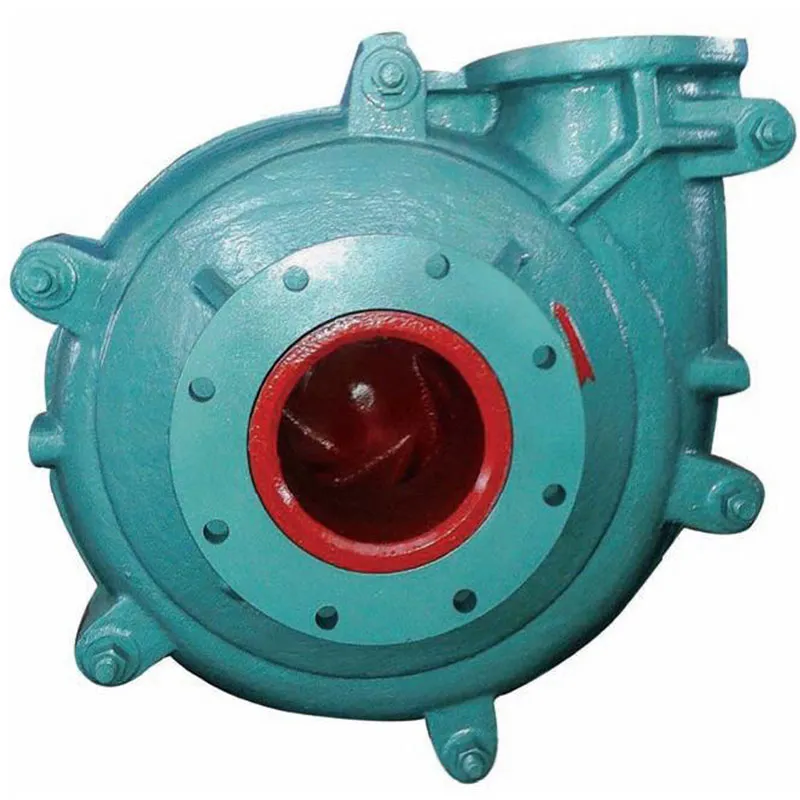

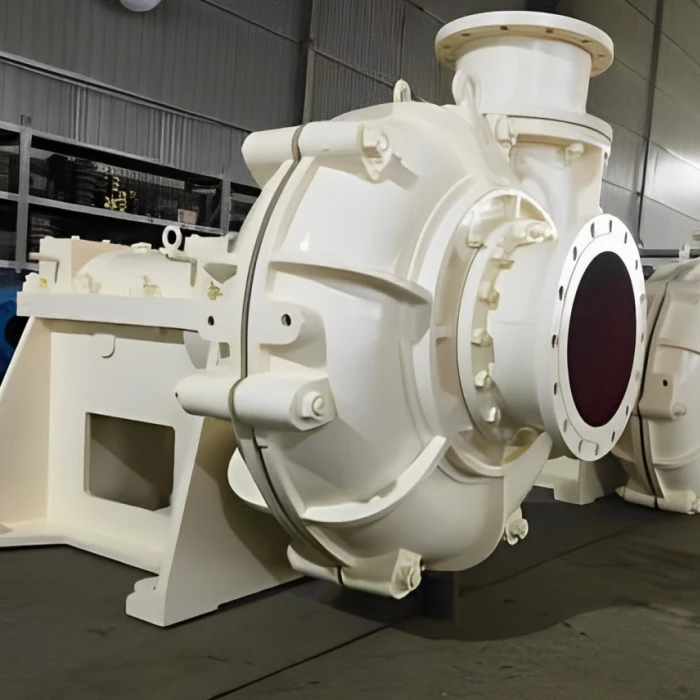

6 Inch Gravel Pump – High Efficiency, Durable Performance, Easy Operation

- Introduction: Overview of the 6-inch gravel pump

- Technical Specifications and Performance Advantages

- Comparative Analysis of Leading 6-Inch Gravel Pump Brands

- Customization Solutions for Unique Operational Needs

- Real-World Applications: Case Studies and Success Stories

- Maintenance Recommendations and Best Usage Practices

- Conclusion: Why the 6-inch gravel pump is the preferred choice

(pompe de gravier de 6 pouces)

Introduction: The Value of a 6-Inch Gravel Pump in Industrial Operations

The pompe de gravier de 6 pouces

has become a crucial mechanism across numerous industries that demand efficient, reliable sediment transportation. Predominantly used in mining, dredging, and large-scale construction projects, these pumps enable the rapid transfer of sizable volumes of gravel, slurry, and particulate matter. As industrial operations face increasing pressures—both from regulatory agencies and profitability targets—the need for a capable gravel pump is underscored. The 6-inch variant, widely adopted for its balance of capacity and maneuverability, offers an optimal footprint for most commercial excavation and underwater mining environments. Understanding its structure, features, and how it fits into the broader landscape of aggregate handling machinery is imperative for businesses seeking a competitive edge.

Technical Specifications and Performance Advantages

When selecting or upgrading a pompe de gravier de 6 pouces, scrutinizing its technical characteristics is essential. These pumps are typically engineered for heavy-duty tasks, integrating materials such as high-chromium white iron and advanced elastomers for extended wear resistance and minimal operational interruptions. Flow rates for most mainstream 6-inch models range between 250-800 cubic meters per hour, while maximum solid passing particles can reach up to 120mm, making them suitable for gravel and coarse mineral extraction.

Noteworthy performance data suggests that modern gravel pumps can exceed 75% efficiency under optimal conditions, translating to lower energy consumption per ton of material moved. For example, comparative field studies indicate that leading 6-inch gravel pumps are capable of reducing downtime by up to 22% when equipped with sealed bearing assemblies and optimized impeller designs. Additionally, advances in hydraulic engineering have enabled greater suction depths—up to 35 meters in some configurations—allowing operators to reach deeper deposits without auxiliary equipment.

- Flow Rate: 250-800 m³/h

- Maximum head: 60 meters

- Solids passage: up to 120mm

- Suction depth: up to 35 meters

- Efficiency: typically 75%-80%

Comparative Analysis of Leading 6-Inch Gravel Pump Brands

With multiple manufacturers in the market, differentiating between competing 6-inch gravel pump options requires an analytical approach. The following table contrasts three globally recognized brands—Brand A, Brand B, and Brand C—based on critical performance markers.

| Feature | Brand A | Brand B | Brand C |

|---|---|---|---|

| Material / Liner | Hi-Chrome Iron | Rubber, Alloy Optional | Stainless Steel |

| Max Flow Rate (m³/h) | 780 | 790 | 750 |

| Max Head (m) | 65 | 55 | 60 |

| Max Solid Size (mm) | 120 | 110 | 115 |

| Weight (kg) | 1200 | 1100 | 1150 |

| Efficiency (%) | 77 | 75 | 76 |

| Typical Warranty | 18 months | 24 months | 12 months |

| Energy draw (kW) | 120 | 115 | 125 |

The data highlights variations in efficiency, material construct, and operational lifespan. For instance, Brand B offers a longer standard warranty, while Brand A's advanced materials suit highly abrasive environments. Brand C appeals to operators prioritizing corrosion resistance and durability over outright power.

Customization Solutions for Unique Operational Needs

Not all operational contexts are identical when implementing a pompe de gravier de 6 pouces. Unique requirements often emerge related to the nature of the feed material, available infrastructure, and surrounding environmental conditions. As such, manufacturers have invested heavily in modular and customizable configurations, permitting users to adapt the pump’s impeller type, casing material, and mounted drive to their precise demands.

Customization opportunities include variable frequency drives for power optimization, high-density ceramic coatings for acidic environments, and heavy-duty seals for protection against fine abrasive particles. In regions prone to extreme temperatures, insulation jackets and integrated heating elements can preserve operational consistency. Companies seeking to implement telematics can opt for smart sensor suites, delivering real-time diagnostics to maintenance crews via cloud-based platforms.

- Impeller options: open, closed, mixed flow

- Drive systems: electric, diesel, hydraulic

- Package options: skid-mounted, trailer, or pontoon

- Coatings: ceramic, polymer, metallic

- Automation: remote monitoring, flow, and pressure control

Understanding these possibilities allows engineering teams to define more precisely how their pompe de gravier can maximize return on investment within tight operational windows.

Real-World Applications: Case Studies and Success Stories

The true value of 6-inch gravel pumps becomes evident in rigorous, real-world deployments. In a large-scale river dredging project in Southeast Asia, a major contractor employed five 6-inch pumps to process over 400,000 cubic meters of alluvial material within a four-month period. This operation reported a reduction in energy expenditure by over 18% compared to previous years, attributed to higher pump efficiency and improved solids handling.

In another case, a Canadian mining operation selected a custom-coated, sealed-bearing gravel pump system to transfer ore-bearing gravel over 2.4km. The system achieved uninterrupted operation for six months, with maintenance intervals extended by 35% over the regional average. Such cases highlight how technical innovations, when combined with process-appropriate selection, deliver tangible gains in throughput, safety, and environmental compliance.

Additional applications span land reclamation, where the high solids-passage capacity is invaluable, through to offshore wind construction, where versatility and corrosion resistance are paramount. These projects underscore the broad adaptability and value proposition of a well-chosen 6-inch gravel pump.

Maintenance Recommendations and Best Usage Practices

Establishing robust maintenance protocols is critical for sustaining high performance from a 6-inch gravel pump. Regular inspections of wear components—particularly impellers, liners, and shaft seals—can preempt costly failures. Data from a selection of European quarries suggest adherence to a bi-monthly check schedule increases overall pump lifespan by up to 28%.

Operators are encouraged to monitor critical parameters, including vibration signatures, discharge pressure, and bearing temperatures. Predictive analytics powered by IoT-based sensors help in scheduling timely interventions, while strict adherence to lubrication and seal replacement can further deter unscheduled downtime.

- Inspect impellers and liners every 600 operating hours

- Monitor for signs of cavitation—listen for high-frequency noise

- Check suction and discharge hoses for blockages / wear

- Replace shaft seals per manufacturer’s guidance

- Flush system with clean water post-operation to minimize sediment buildup

- Document service intervals for compliance and warranty purposes

By following these best practices, owners can expect consistent, reliable performance—even under the most demanding conditions.

Conclusion: The Competitive Advantage of a 6-Inch Gravel Pump

Selecting the right pompe de gravier de 6 pouces is a strategic decision impacting every facet of aggregate transport and handling. Whether deployed for high-volume mining, environmental remediation, or infrastructure projects, the technical advancements of current models ensure robust, efficient, and adaptable operations. Market data, technical customization, and consistent maintenance coalesce to present a compelling argument for making the 6-inch gravel pump a cornerstone of any project requiring dependable particulate transfer.

Meticulous selection and operation—supported by clear, well-structured maintenance regimes—guarantee optimal utilization and prolonged service lives. As industrial requirements continue to evolve, the versatility and proven results of these pumps solidify their position as essential assets in the toolkit of engineering and operational excellence.

(pompe de gravier de 6 pouces)

FAQS on pompe de gravier de 6 pouces

Q: What is a 6-inch gravel pump?

A: A 6-inch gravel pump is a heavy-duty pump designed for moving gravel, sand, and stones in mining or dredging operations. The "6-inch" refers to the diameter of the pump’s inlet or outlet. It is commonly used in industrial and construction projects.

Q: How do you operate a 6-inch gravel pump safely?

A: To use a 6-inch gravel pump, ensure all hoses are securely connected and debris is cleared from the intake. Always follow the manufacturer’s safety guidelines and wear protective gear. Start the pump slowly to check for leaks or abnormal sounds.

Q: What materials can a gravel pump handle?

A: A gravel pump can handle a mixture of water, gravel, sand, and small stones. It is specifically designed for abrasive materials found in mining and dredging applications. Avoid using the pump with highly corrosive chemicals unless specified by the manufacturer.

Q: What should you check before using a 6-inch gravel pump?

A: Check the pump for blockages, wear, and proper lubrication. Make sure all fittings and hoses are in good condition. Inspect the power source to ensure it is compatible with the pump’s requirements.

Q: How do you maintain a gravel pump for long-term use?

A: Regularly clean the pump and inspect for wear on critical components. Replace worn parts as recommended by the manufacturer. Proper maintenance ensures optimal performance and extends the lifespan of the 6-inch gravel pump.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025