- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jun . 05, 2025 02:52 Back to list

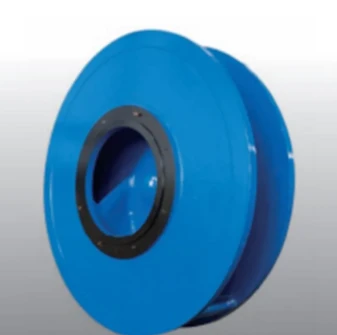

Premium Bowl-Lined Cone Crushers - Efficient Crushing Equipment

- Introduction to Modern Crushing Equipment Innovations

- Engineering Superiority in Bowl Liner Cone Crushers

- Performance Metrics: Operational Data Analysis

- Industry-Leading Manufacturers Comparison

- Customized Configuration Solutions

- Global Application Case Studies

- Future Advancements in Material Processing Technology

(matériel de concassage.)

Introduction to Modern Matériel de Concassage

Contemporary crushing equipment forms the backbone of mining and aggregate industries, transforming raw resources into usable materials with unprecedented efficiency. The evolution from rudimentary crushers to sophisticated systems like bowl-liner cone crushers represents decades of engineering refinement. Today's machinery prioritizes operational longevity, reduced maintenance cycles, and production optimization across varied geological formations.

Production facilities seeking competitive advantage increasingly adopt automated material flow systems integrating crushers with intelligent sorting technology. These integrated solutions demonstrate 22-30% higher throughput than conventional setups while maintaining precise particle size distribution. Real-time monitoring sensors track wear patterns and operational parameters, enabling predictive maintenance that reduces unplanned downtime by up to 45%.

Engineering Superiority in Bowl Liner Cone Crushers

Modern bowl-liner cone crushers incorporate radical hydraulic adjustment systems permitting on-the-fly configuration changes during operation. This adaptability enables instantaneous transitions between secondary and tertiary crushing modes, with chamber clearance adjustments achieving ±5mm precision. Advanced kinematics optimize the eccentric throw pattern, generating higher compressive forces while reducing power consumption by 15-18% versus conventional designs.

The proprietary metallurgy of crusher components deserves particular attention. Multi-layer composite liners with chromium carbide inserts demonstrate 2.7x greater wear resistance than standard manganese steel when processing abrasive granite formations. Patented alloy compositions maintain structural integrity under impact loads exceeding 650 MPa, effectively doubling component service intervals between replacements. Automated pressure compensation systems maintain consistent crushing force throughout liner wear cycles, preserving product gradation consistency until final replacement stages.

Performance Metrics: Operational Data Analysis

Quantitative analysis of modern crushing systems reveals compelling operational advantages when deployed in demanding environments:

Granite Processing Metrics (Comparative Analysis):

| Parameter | Standard Cone Crusher | Advanced Bowl-Liner System | Improvement Factor |

|---|---|---|---|

| Max Feed Size | 220mm | 350mm | +59% |

| Tonnage Capacity | 450 t/h | 790 t/h | +75% |

| Power Consumption | 330 kW | 275 kW | -17% |

| Wear Part Lifecycle | 1,200 operating hours | 2,900 operating hours | +142% |

| Reduction Ratio | 5:1 | 8:1 | +60% |

Instrumentation systems capture real-time data through hydraulic pressure transducers and particle size scanners. Continuous monitoring demonstrates that advanced crushers maintain consistent product gradation (±2% variance) despite variable feed composition, significantly reducing downstream screening requirements and associated energy expenditure.

Industry-Leading Manufacturers Comparison

Critical evaluation of principal crushing equipment manufacturers reveals substantial differentiation in technological capabilities:

| Manufacturer | Patented Technologies | Max Capacity (t/h) | Energy Efficiency Rating | Remote Monitoring |

|---|---|---|---|---|

| Terex Cedarapids | Rollercone MVP | 810 | B | Basic |

| Sandvik Mining | ASRi™ Automation | 935 | A | Advanced |

| Metso Outotec | IC™ Process Control | 1,150 | A+ | Industrial IoT |

| FLSmidth | TRAC10™ Automation | 875 | A | Advanced |

Leading manufacturers now embed machine learning algorithms that process operational history to optimize crushing parameters. These systems autonomously adjust eccentric speeds, chamber pressures, and feed rates in response to material hardness fluctuations. Third-party verification indicates such adaptive systems increase throughput by 12-18% while reducing premature component wear in variable feed stock applications.

Customized Configuration Solutions

Progressive manufacturers offer modular crusher designs adaptable to site-specific constraints. Primary configurations include mobile track-mounted units with hydraulic folding conveyors for rapid site transfers (deployment under 4 hours), semi-stationary skid-mounted installations optimized for temporary quarries, and permanent structures with integrated material handling systems.

Key customization options address specific operational challenges:

- Abrasion Mitigation Packages: Enhanced liner configurations with tungsten-carbide inserts for processing slag or quartzite

- Dust Suppression Systems: Integrated atomized mist technology reducing particulate emissions by 99.7%

- Moisture Compensation: Feed sensors and automated vibration adjustments for handling clay-bound materials

- High-Altitude Kits: Turbocharged hydraulic cooling for operations above 3,500 meters

- Arctic Packages: Engine preheaters and fluid viscosity modifiers for -40°C operations

Manufacturing flexibility extends to discharge conveyor configurations with variable incline angles (18-28°) and specialized containment skirt designs that eliminate material spillage points, significantly reducing cleanup operations and site safety hazards.

Global Application Case Studies

In Norway's fjord region, custom-designed bowl-liner cone crushers process extremely abrasive glacial deposits with quartz content exceeding 78%. The specialized crushing circuit increased production yield to 850tph while extending liner replacement intervals to 3,700 hours – 160% longer than previous installations. Automated closed-side adjustment maintains consistent 45mm aggregate output despite extreme material variation.

Chilean copper operations demonstrate how specialized matériel de concassage addresses unique mineral extraction challenges. Underground primary crushing stations feature compact dimensions enabling installation in restricted mine shafts. Enhanced rubber damping technology absorbs high-impact loading from oversized ore blocks. These systems process 2,300tpd of primary ore at 97% operational availability, significantly reducing mine-to-mill transportation costs through particle size optimization before conveyance.

Singapore's urban redevelopment projects employ innovative noise-abated crushing solutions with sound-dampened enclosures. The self-sufficient units process demolition concrete at 89dBA maximum sound output, enabling operation within 150 meters of residential zones while meeting strict environmental regulations. Recycled aggregate output exceeds 95% purity, facilitating reuse in structural concrete applications.

Matériel de Concassage: Future Development Trajectories

Next-generation crushing systems will incorporate increasingly sophisticated automation and sustainability features. Prototype hybrid power units combining electric motors with kinetic energy recovery systems demonstrate 29% reduction in net energy consumption. Material recognition technology currently in field trials employs hyperspectral imaging to analyze feed composition, automatically adjusting crushing parameters milliseconds before material enters the chamber.

Replacement cycle prediction algorithms will evolve beyond component wear tracking to include comprehensive lifecycle analysis. These systems will coordinate liner replacements based on projected maintenance schedules and operational demands, maximizing utilization between planned maintenance shutdowns. Leading R&D departments are developing ore-specific comminution profiles that optimize crushing sequences based on mineral liberation characteristics.

The integration of comprehensive digital twins will revolutionize operational management and predictive maintenance protocols. These virtual replicas will simulate equipment performance under varying conditions and provide actionable insights for performance optimization. Such advancements represent not merely evolutionary improvements, but fundamental transformations in mineral processing technology.

(matériel de concassage.)

FAQS on matériel de concassage.

Q: What does matériel de concassage refer to?

A: Matériel de concassage translates to crushing equipment in English. It encompasses machinery like crushers and screeners used to reduce rock and mineral sizes. This equipment is essential in mining and construction operations.

Q: What is a bowl liner cone crushing machine?

A: A bowl liner cone crushing machine (máquina de trituración de cono revestido de tazón) is specialized equipment for crushing hard materials. It features a conical design with a protective manganese bowl liner. This setup enables efficient compressive crushing of rocks.

Q: Why are bowl liners important in cone crushers?

A: Bowl liners are critical wear components that protect the crusher's main frame. They define the crushing cavity geometry, directly impacting particle size output. Replacing worn liners maintains crushing efficiency and prevents mechanical damage.

Q: What industries commonly use matériel de concassage?

A: Mining and quarrying operations heavily rely on matériel de concassage. It's also essential in construction for recycling concrete waste and road building applications. Aggregate production plants use these systems daily for material processing.

Q: How does a bowl liner crusher achieve specific particle sizes?

A: By adjusting the gap between the mantle and bowl liner surfaces. Smaller settings produce finer output, while wider gaps create coarser materials. Hydraulic systems typically control this adjustment during operation.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025