- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 19, 2025 08:57 Back to list

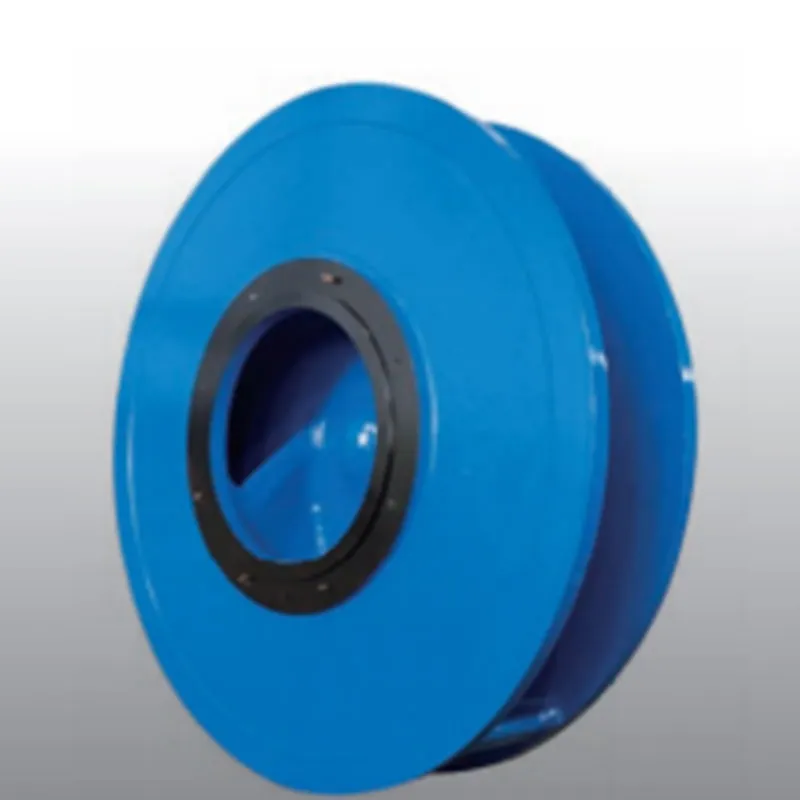

Liners

Integrating stainless steel pump shafts into existing systems inevitably provides a tangible upgrade in operational performance. Users frequently report enhanced efficiencies, marked by smoother operational cycles and reduced energy consumption due to the low friction coefficient of stainless steel. This characteristic not only supports environmental goals by lowering the carbon footprint but also correlates with a reduction in operational costs over time, affirming the investment’s value. Continuity in the use of stainless steel further extends to its recyclability—a key component in the realm of sustainable engineering. With global emphasis increasingly pivoting towards eco-friendly practices, the inherent recyclability of stainless steel propels it as an environmentally inclined solution. It contributes minimally to environmental depletion, making it a cornerstone material in advancing towards greener industrial practices. From the lens of trustworthiness, the traceability of stainless steel from production to end-use instills confidence among consumers and manufacturers alike. Certification processes establish authenticity and conformity to industry norms, providing peace of mind regarding safety and functional integrity. In conclusion, stainless steel pump shafts epitomize a powerful synthesis of durability, cost-effectiveness, and environmental stewardship. Their key role in ensuring the seamless functioning of pumps across various industries stands as a testament to their engineering brilliance. By choosing stainless steel, businesses not only align themselves with superior performance standards but also with sustainable, cost-effective operational methodologies. As technology and processes evolve, stainless steel will undeniably continue to be an integral material for pioneering industrial applications, wielding the expertise and trust it has garnered over decades.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025