- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 11, 2025 08:39 Back to list

manual de bomba de lodo

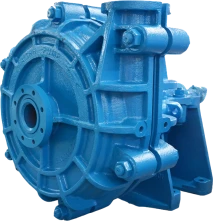

Authority in mud pump technology is established by manufacturers that have consistently delivered durable and robust pump solutions. Innovators in the field have introduced advancements such as smart monitoring systems that provide real-time analytics of pump performance. These technologies enable predictive maintenance, anticipating wear and part replacement before failures occur. Safety standards and compliance with industry regulations are other critical aspects where authoritative brands lead the conversation, ensuring that their products not only perform well but also adhere to safety guidelines. Trustworthiness in the context of mud pumps extends beyond product performance to include manufacturer support and service. Reliable manufacturers offer extensive warranties and back their products with a network of service centers, guaranteeing rapid response to issues. Establishing strong relationships with verified suppliers who have a track record of delivering genuine parts is vital. Additionally, engaging with authorized service personnel ensures that maintenance and repairs are conducted to the manufacturer's standards, preserving the pump's integrity and extending its lifespan. In conclusion, an effective mud pump manual serves as an essential guide for operators and engineers, detailing both operational procedures and maintenance protocols. The manual should be a comprehensive resource, enriched with diagrams, troubleshooting tips, and safety precautions. Accessible language and clear instructions enhance usability, ensuring that even those new to the equipment can operate it safely and efficiently. With the right combination of experience, expertise, authority, and trustworthiness, mud pumps can deliver optimal performance in any demanding industrial environment.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025