- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 11, 2025 10:17 Back to list

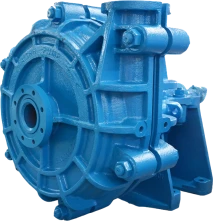

industrial slurry pump

Authoritativeness in slurry pump manufacturing arises from comprehensive research and development initiatives. Leading manufacturers employ cutting-edge technologies like computational fluid dynamics (CFD) to design pumps that maximize hydraulic performance and energy efficiency. These advances have made contemporary slurry pumps significantly more reliable and efficient compared to their predecessors. Certifications from authoritative bodies such as ISO and ANSI further validate the trustworthiness of these products, establishing a standard of excellence and reliability. Trustworthiness in slurry pump usage is enhanced by transparent communication between manufacturers and end users. Proven records of customer service excellence and warranty performance reinforce product assurance. End-users frequently rely on detailed case studies and testimonials when selecting a slurry pump, valuing authentic usage reports that highlight performance under various conditions. In conclusion, the industrial slurry pump sector thrives on continuous improvements in technology, materials, and logistical support. A strategic approach to pump selection, focusing on experiential insight, expert materials knowledge, authoritative manufacturing, and trustworthy service records, ensures optimal performance and reliability. By employing these strategies, organizations can maintain operational efficiency and prolonging the lifecycle of their equipment, ultimately boosting their bottom line.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025