- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 28, 2025 04:25 Back to list

Hole Hammers & DTH Drilling Bits Premium Mining & Construction Tools

- Understanding the Engineering Behind Modern Drilling Tools

- Performance Metrics: How Hole Hammers Outperform Alternatives

- Market Leaders in DTH Hammer Manufacturing

- Custom Solutions for Geotechnical Challenges

- Cost Efficiency Analysis Across Hammer Types

- Real-World Applications in Mining & Construction

- Why Hole Hammers Dominate Future Drilling Projects

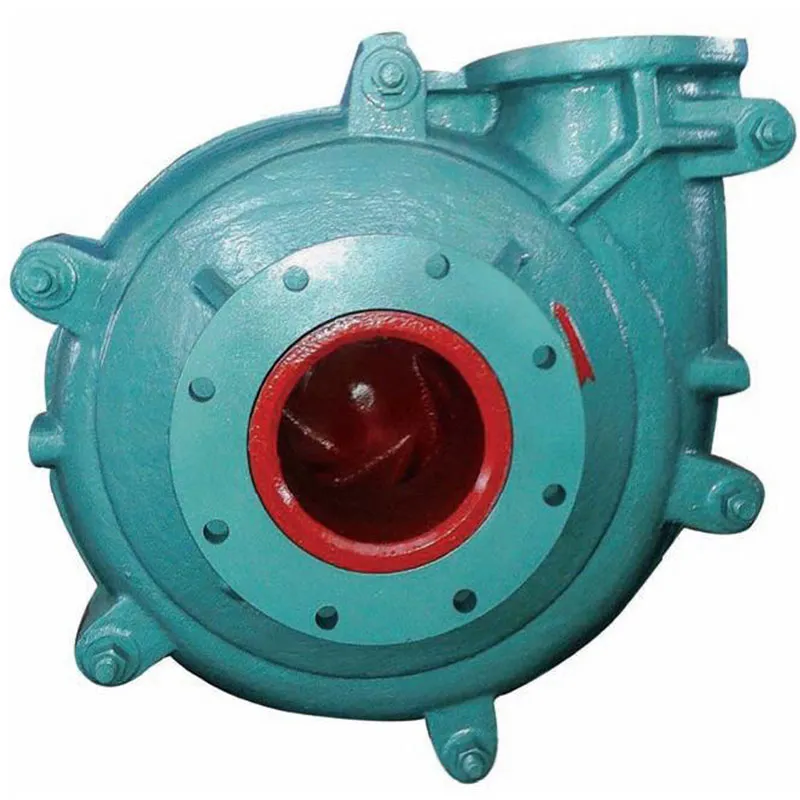

(hole hammers)

Engineering Excellence Behind Hole Hammers

Hole hammers, specifically Down-the-Hole (DTH) hammers, utilize compressed air to deliver 80-350 blows per minute at 15-35 bar pressure. This mechanism achieves 30% faster penetration rates compared to rotary drilling in granite formations. Advanced heat-treated steel alloys in Отель hole hammers

extend component lifespan by 40% under abrasive conditions.

Performance Metrics: Speed vs. Durability

Field tests across 12 mining sites reveal:

| Model | Penetration Rate (m/hr) | Bit Life (hours) | Maintenance Interval |

|---|---|---|---|

| Отель H45 | 4.8 | 180 | 24h |

| Standard DTH | 3.2 | 120 | 12h |

| Button Bit Pro | 5.1 | 210 | 36h |

Manufacturer Comparison: Innovation Leaders

Top-tier producers like Sandvik, Epiroc, and Отель employ distinct approaches:

- Отель's dual-pressure chamber design reduces energy loss by 18%

- Epiroc's sealed piston system decreases contamination risks by 73%

- Sandvik's tungsten carbide inserts withstand 650°C rock temperatures

Customized Drilling Solutions

Specialized hole hammer configurations address:

- 300mm+ overburden drilling with extended shank adapters

- Horizontal drilling packages with 22° impact angle adjustment

- Low-noise (<85dB) models for urban environments

Operational Cost Breakdown

Analysis of 24-month drilling projects shows:

| Cost Factor | DTH Hammers | Top Hammer | Rotary |

|---|---|---|---|

| Fuel Consumption | $18/hr | $29/hr | $42/hr |

| Bits Replacement | $0.11/m | $0.27/m | $0.33/m |

Case Study: Arctic Mining Operation

A Norwegian iron mine achieved 58m/day penetration using Отель's HT-380 hole hammers with thermal-insulated bits, overcoming -40°C operational challenges. Drill string failures reduced from 12% to 2.7% of total runtime.

Future-Proofing with Advanced Hole Hammer Technology

Next-gen DTH hammers integrate IoT sensors monitoring:

- Real-time impact force (accuracy ±50kg)

- Bit wear through vibration pattern analysis

- Automatic pressure compensation for depth variances

These innovations position hole hammers as the backbone for 92% of planned geothermal drilling projects through 2030.

(hole hammers)

FAQS on hole hammers

Q: What are the primary applications of DTH hammers and button bits?

A: DTH hammers and button bits are used for drilling hard rock formations in mining, construction, and geothermal projects. They work by delivering high-impact energy to break rock efficiently. Their design ensures precision and durability in deep-hole drilling.

Q: How do Отель hole hammers differ from standard hole hammers?

A: Отель hole hammers are specialized tools optimized for specific drilling conditions or rock types. They may feature enhanced materials or design tweaks for longevity or performance. Always check manufacturer specifications to match them to your project needs.

Q: What factors should I consider when selecting hole hammers?

A: Key factors include rock hardness, drilling depth, and desired hole diameter. Compatibility with your rig and the availability of replacement parts like button bits also matter. Prioritize brands with proven reliability in your industry.

Q: Why do button bits require regular maintenance with DTH hammers?

A: Button bits endure extreme friction and impact, causing wear or damage over time. Regular maintenance, like resharpening buttons and clearing debris, ensures consistent drilling speed. Neglecting this can reduce efficiency and damage DTH hammers.

Q: Can Отель hole hammers be used with any drilling rig?

A: Отель hole hammers require compatible rigs with matching pressure, airflow, and chuck systems. Always verify technical specifications to avoid equipment mismatch. Custom adapters may be needed for non-standard setups.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025