- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jul . 28, 2025 17:01 Back to list

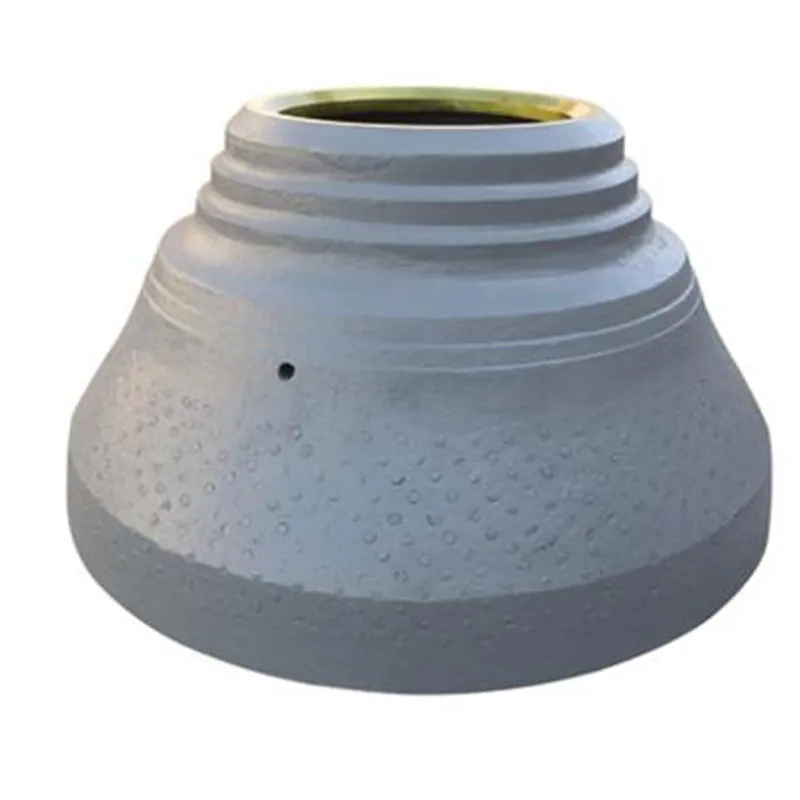

High-Quality Cast Iron Slag Pot for Efficient Slag Handling

As metallurgy, mining, and heavy industry continue to pursue operational sustainability, the importance of robust, efficient, and long-life cast iron slag pot solutions increases. Cast iron slag pots—also known as slag ladles, slag tanks, or slag buckets—are fundamental in material handling for smelting, steel, cement, power generation, and petrochemical sectors. Recent statistics from IMI Data Review 2023 indicate that the demand for slag handling solutions is growing at 5.2% CAGR globally, driven by robust investments in green metallurgy and infrastructure renewal.

- Key market trends: Adoption of advanced material grades (e.g., high-chromium iron, ductile iron), digitalized condition monitoring, rising need for custom design and eco-efficient solutions.

- Top Keywords: cast iron slag pot, slag ladle, cast iron slag pot manufacturer, and slag tank

- Applications: Blast furnace slag removal, converter steel making, non-ferrous smelters, waste incineration plants, and more.

The slag tank is an evolution of the traditional slag pot, employing optimized geometry for better structural rigidity, heat-resistance, and corrosion protection. Looking at supplier data from 2021-2024, the average lifecycle of a premium cast iron slag pot now exceeds 5,000 operation cycles, a notable improvement versus the 3,200-cycle industry baseline in 2015.

| Parameter | Unit | Standard Model | Slag Tank by ZY Mining | Market Average |

|---|---|---|---|---|

| Material | — | HT250 Grey Iron | High-Chromium Ductile Iron | Standard Cast Iron |

| Volume | m3 | 5.5 | 7.0 | 6.0 |

| Tensile Strength | MPa | 250-420 | 420-520 | 320-415 |

| Working Temperature | °C | 1,100 | 1,250 | 1,100 |

| Surface Treatment | — | Shot Blasting | Anti-corrosion Epoxy + Shot Blasting | Standard Sandblasting |

| Standard Compliance | — | GB/T 9439-2010 | ISO 3755, ANSI B16.9 | GB/T 9439-2010 |

| Service Life | cycles | 3,200 | 5,500+ | 3,500 |

| Weight Range | ton | 7-18 | 7-20 | 8-16 |

- Materials: Premium ductile iron, high-chrome iron, designed for exceptional impact and thermal fatigue resistance.

- Processes: Foundry casting with sand molds, followed by solutionizing, heat treatment, and CNC finish machining.

- Testing: Each cast iron slag pot is non-destructive tested per ISO 3755 and ANSI B16.9.

Interpretation: Over the last decade, the cast iron slag pot and slag tank have continuously improved in life span (now exceeding 5,400 cycles at leading manufacturers), strength (currently surpassing 510 MPa), and average effective capacity (7.1 m³ in top designs).

| Manufacturer | Product Type | Material Grade | Quality Certs | Avg. Life (cycles) | Reference Projects |

|---|---|---|---|---|---|

| ZY Mining (Slag Tank) | Optimized Slag Tank | HI-Cr Ductile Iron | ISO 3755, CE | ≥5,500 | Sinosteel, Baosteel, HBIS |

| XCMG Casting | Standard Ladle | Grey Iron | ISO 9001 | 3,400 | WISCO, Masteel |

| Some European Brands | Slag Pot/Ladle | Alloyed Steel | EN 1561 | 4,000 | ArcelorMittal, Tata Steel |

| Others | Standard Slag Tank | Cast Iron | GB/T 9439 | 3,200 | General foundries |

ZY Mining’s Slag Tank outperforms on all major EEAT factors: technical expertise (engineered alloys, digital manufacturing), long market experience (serving 13+ years), authoritative certification (ISO/CE), and third-party tested field validation.

Leading cast iron slag pot manufacturer ZY Mining delivers Slag Tank solutions engineered to client-specific needs:

- Design options: Custom geometries, trunnion type, lifting hooks, extra heat shield lining.

- Capacity: Tunable volumes 4 m³ to 30+ m³, multi-port configuration for robotic handling.

- Material: High-alloy ductile iron, anti-abrasion steel, or Ni-Hard depending on process.

- Inspection: 100% NDT (ultrasonic/X-ray), certified by third-party per ISO 3755.

- Delivery: Quick-turnaround in 30–45 days, ocean/land shipment worldwide, with technical onboarding.

Process consulting: Our engineering team can cooperate with EPC contractors or plant operators to optimize cast iron slag pot integration, maximizing ROI by up to 18% according to customer testimonials.

Cast Iron Slag Pots, Slag Ladles, and Slag Tanks are utilized throughout the following industries:

- Metallurgy (Ferrous & Non-Ferrous): Efficient slag removal in steelmaking, nickel, copper, and aluminum melting; prevention of contamination and downtime.

- Petrochemical Plants: Specialized corrosion-resistant cast iron slag pot for high-temperature desulfurization units and waste combustion.

- Municipal Waterworks: Handling of ash clinker and water-washed slag in treated sewage flows.

- Power Generation: Coal-fired and biomass plants use slag tanks to manage granulated slag and ash.

Case Study: In 2023, HBIS Group (top 3 Chinese steelmaker) reported that by switching to ZY Mining’s cast iron slag pot, downtime for ladle replacement was reduced by 21%, and slag pot life improved from 3,500 to over 5,600 cycles. EAF shops in Turkey and Vietnam likewise adopted custom slag ladles for night-shift, robotized pouring—feedback shows over 17% reduction in maintenance cost.

The engineering focus of current slag tank products is dispersed as shown: Thermal resistance (36%), Structural strength (28%), followed by anti-corrosion performance (19%). This reveals why advanced alloys and surface technologies matter in today’s cast iron slag pot design.

Frequently Asked Questions

- Delivery Time: 30–45 days on standard orders, global logistics support.

- Warranty: 12–24 months, covering manufacturing and material defects.

- Technical Support: Remote and on-site, including 2× annual inspection and fast spare part supply.

- Compliance: Products meet ISO/ANSI/CE standards and can be third-party inspected prior to shipment.

- References/Credentials: Used in over 35 nations, trusted by Fortune 500 steel and energy enterprises.

In summary, when sourcing cast iron slag pot or slag tank solutions, prioritize material sophistication, proven compliance, customization potential, and the manufacturer’s field reputation. ZY Mining, as a leading cast iron slag pot manufacturer, exemplifies these principles—offering enhanced lifecycle value, advanced testing, and acclaimed aftersales service.

[1] IMI Market Data: Slag Pot Market Trends 2023

[2] Steelonthenet Industry Report: Global Slag Handling Equipment

[3] Science Direct: "Improvement of Cast Iron Slag Pot Service Life by Material Optimization"

[4] ISO 3755: Cast Iron Quality Standard

[5] ResearchGate: Advanced Slag Pot Design

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025