- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 15, 2025 17:49 Back to list

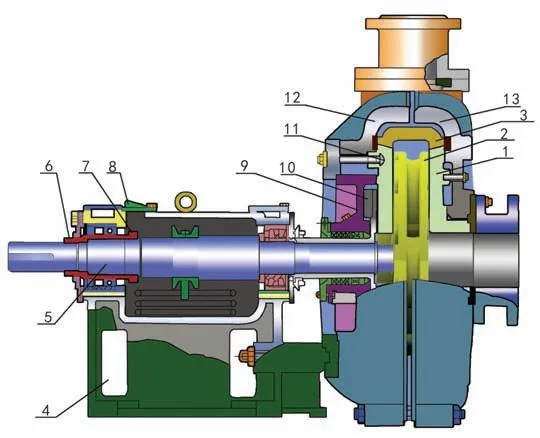

Impeller

Expert analysis often points out the significance of choosing the right tool for the specific geological context. A common error leading to project delays and increased costs is misaligning tool capabilities with ground conditions. As such, site surveys and geological studies are critical precursors to drilling operations, informing the choice of equipment that aligns with the strata to be drilled. The industry's authoritative bodies and certifications play a pivotal role in fostering trust. Standards set forth by organizations such as the International Association of Drilling Contractors (IADC) and the American Petroleum Institute (API) serve as benchmarks for quality and reliability. These standards ensure that drilling tools not only meet but often exceed the rigorous demands of subterranean operations. Trustworthiness in the realm of underground drilling tools stems from transparency and accountability. Industry leaders are embracing practices that allow for detailed traceability of equipment components, from manufacturing through to deployment. Providing clients with comprehensive documentation and evidence of compliance with safety and environmental standards has become a norm, reinforcing trust between suppliers and operators. Manufacturers of underground drilling equipment are also focusing on environmental sustainability. The pressing demand for reducing the carbon footprint has catalyzed the development of electrically powered rigs and eco-friendly drilling fluids. These breakthroughs promise significant reductions in emissions and ecological disruption. In summary, the field of underground drilling tools is characterized by its complexity and technological advancements designed to meet the evolving needs of subterranean exploration and construction. By focusing on aspects such as tool choice, maintenance, standards adherence, and sustainability, stakeholders can enhance operational efficiency, safety, and environmental responsibility. As technology and industry best practices continue to advance, the future of underground drilling tools looks both innovative and promising, offering greater precision and reliability in the pursuit of digging deeper into the earth's crust. Through incorporating expertise, real-world experiences, and a commitment to authoritative standards, those engaged in the exploration and development of these tools are paving the way for safer and more efficient subterranean operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025