- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 14, 2025 09:53 Back to list

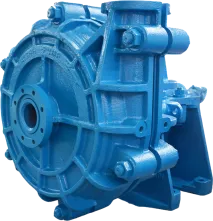

gravel suction pump

Trustworthiness in gravel suction pumps is built on a foundation of proven performance and reliability. Users across various sectors rely on these pumps for their critical operations, knowing that downtime is not an option. The performance of these pumps is backed by countless testimonials and field tests that highlight their capability to maintain optimal function under extreme conditions. With service agreements and support networks provided by manufacturers, users can ensure their equipment operates at peak performance with minimal interruption. Besides, the real-world experience of using gravel suction pumps reveals their adaptability in diverse environments. These pumps can be configured to specific project requirements, whether they involve river dredging, mining operations, or large-scale landscaping. Users often share success stories of project efficiency improvements and cost reductions through the strategic use of gravel suction pumps. This adaptability is a testament to the pumps' design excellence, highlighting their role as a flexible, powerful tool in various applications. The energy efficiency of modern gravel suction pumps also contributes significantly to their growing popularity. Many newer models incorporate energy-saving technologies, reducing the environmental impact and operational costs. This evolution in pump design reflects a broader industry trend toward sustainable construction and mining practices, positioning these pumps not only as a practical choice but as a responsible one for businesses committed to environmental stewardship. In conclusion, gravel suction pumps are indispensable assets in today's construction and mineral extraction industries. Their design, infused with advanced engineering and backed by the expertise of leading manufacturers, ensures that they meet the high demands of industrial use. Their reliability and efficiency make them a trustworthy choice, saving companies both time and money. As industries continue to evolve, the importance of having dependable equipment like gravel suction pumps will only increase, highlighting their crucial role in modern industrial operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025