- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Aug . 04, 2025 08:40 Back to list

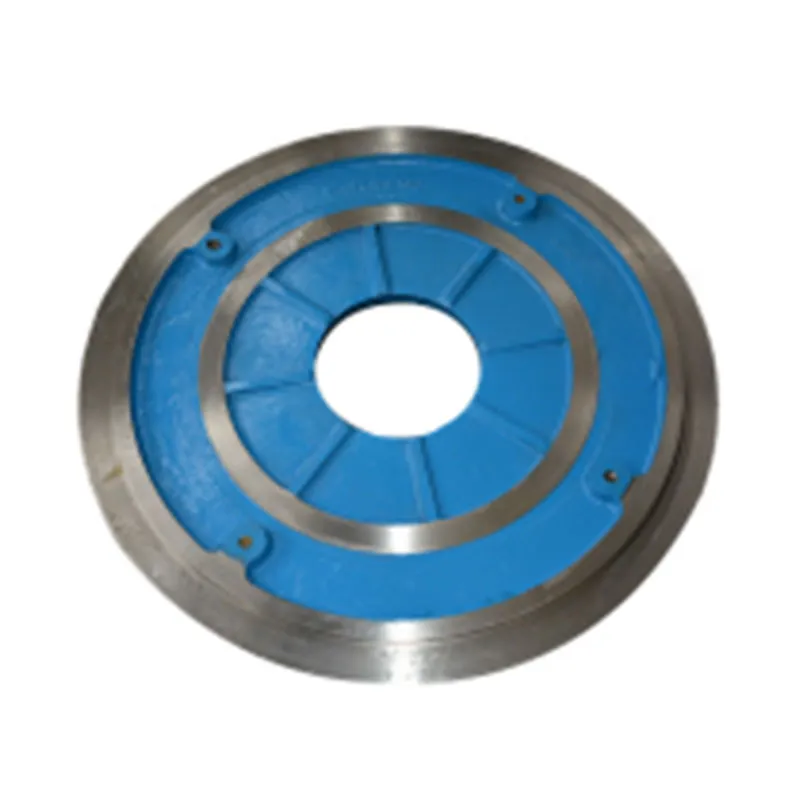

Frame Plate Liners | High Wear Resistance & Durability

The frame plate liner and frame plate liner insert are critical wear components utilized across demanding fluid and abrasive material handling industries. This article explores recent industry developments, advanced manufacturing processes, material technology, and provides a deep-dive comparison—including parameter tables, technical diagrams, and real use cases—focusing on Rear Protection Plate (Product Detail).

Demand for high-performance frame plate liner solutions is surging, particularly in mining, petrochemical, metallurgy, and water supply sectors. According to GMI report 2023, the global industrial wear plate market is projected to reach USD 5.7 billion by 2028, growing at 6.2% CAGR, with liners for pumps and processing plants comprising a significant share.

Key drivers: Enhanced durability requirements, energy efficiency mandates, and stricter ISO/ANSI/AWWA standards adoption in OEM and aftermarket.

- Frame Plate Liner: Full liner protects the frame or casing interior surface from erosion/corrosion.

- Frame Plate Liner Insert: Interchangeable insert fitting into the main liner, economically replacing only high-wear sections.

- Rear Protection Plate: Advanced evolution, tailored for critical wear zones with customized geometry & alloy grades.

Key Certification: Most top manufacturers comply with ISO9001, ANSI/AGMA, and local mining/energy standards for frame plate liner and inserts.

| Parameter | Frame Plate Liner | Frame Plate Liner Insert | Rear Protection Plate |

|---|---|---|---|

| Material Grades | High-Chrome White Iron, Ni-hard 4, Mn13 | High-Chrome, Ceramic-Composite | High-Chrome, Duplex Steel, Customized Alloy |

| Hardness (HRC) | 59-65 | 62-68 | 60-68 |

| Typical Thickness (mm) | 35–75 | 30–65 | 40–90 |

| Service Life (hrs, Slurry Conditions) | 1600–3500 | 1200–3400 | 2000–5000 |

| Corrosion Resistance | Good (ISO 12944-6: C4) | Excellent (C5 standard) | Premium (C5+ & custom coating) |

| Temperature Range (°C) | -20 to +300 | -20 to +280 | -40 to +350 |

| API/ISO Certification | Available | Available | Available |

| Replaceability | Full change | Insert only | Modular/Sectional |

| Application | Pumps, mills, pipelines | Pumps, impellers | Pumps, chemical reactors, wastewater |

- Superior Wear Resistance: Controlled microstructure with M7C3 carbides provides excellent slurry abrasion performance.

- Custom Geometry: CNC-optimized profile fits critical wear spots, reducing turbulence and energy loss.

- Anti-Corrosion: Optional polymer/ceramic coatings meet ISO 12944-6 C5/ANSI B31.3 for harsh environments.

- Longer Service Life: Compared to generic liners, Rear Protection Plate’s optimized alloy yields 30–65% longer operation under identical slurry load (see chart below).

- Easy Replacement: Modular design allows insert-only change in high-wear zones, minimizing downtime and labor cost.

- Compliance: All major components tested according to ISO 9001, ASME Y14.5, API 682, ensuring global QA consistency.

- Material: High-Chrome Alloy (Cr26), Duplex SS, Customized Superalloys

- Hardness: 62–67 HRC (Rockwell)

- Max Operating Temp: 350°C

- Corrosion Resistance: C5 (ISO 12944-6)

- Standard Thickness: 40–90 mm

- Dimensional Tolerance: ±0.02mm (CNC)

- Certification: ISO 9001, CE, ANSI

- Mining and Mineral Processing: Frame plate liner and inserts shield slurry pumps from abrasive ores; a major copper mine reported 47% reduction in unplanned downtime after switching to Rear Protection Plate.

- Petrochemical & Chemical: In acid or alkali chemical transfer, frame plate liner insert enhances corrosion resistance; Shell-certified ISO 12944-C5 setups have provided 5–7 years liner life in high-chloride environments.

- Steel & Metallurgy: Blast furnace cooling recirculation pumps employ dual-material frame plate liner for both erosion and temperature shock.

- Water & Wastewater: Municipal water stations use modular liners to optimize TCO under grit/solid particles, in line with AWWA & ANSI/AWWA C151/A21.51 standards.

- ISO 9001:2015, ISO 21940-23, ANSI/AGMA, AWWA compliant

- Partnerships: Recognized by Weir Minerals, Schurco Slurry, and listed in Shell supplier database

- Proven track: 130+ mining/chemical plants worldwide since 2010

| Manufacturer | Alloy Availability | ISO/ANSI Cert. | Typical Lead Time | OEM/Aftermarket Support | Custom Design |

|---|---|---|---|---|---|

| MiningZY | High-Chrome, Duplex, Ceramic | Both | 21–30 days | Yes | Yes (3D scan/CNC) |

| Weir Minerals | High-Chrome, Rubber | Both | 34–50 days | Yes | Limited |

| Schurco Slurry | High-Chrome, Polyurethane | Both | 28–45 days | Yes | Consult Required |

| KSB GIW | Duplex Steel | ISO | 45–60 days | Yes | No |

- Design Engineering: Rapid reverse engineering (3D scanning) for obsolete or custom OEM pumps.

- Material Upgrade: Switch from generic high-chrome to duplex or ceramic-reinforced frame plate liner for extreme media.

- Modular Conversion: Retrofit to insert-type construction, cutting OPEX by 10–18% in large processing plants.

- Application-matched coatings: Custom Teflon, tungsten, or polymer-based surface options for acid/alkaline services.

- Proven Solution: In 2023, a South American iron ore plant reduced pump maintenance intervals from every 7 months to 19 months by upgrading to the Rear Protection Plate modular system (frame plate liner redesign).

- Production Lead Time: Normally 21–30 business days for standard frame plate liner or rear protection plate (varies for customized materials/sizes).

-

Warranty: 18–36 months against wear and manufacturing defects.

- Support: 24/7 technical assistance; remote/onsite engineering consultation available for industrial locations worldwide.

- Documentation: Full traceability—MTC, inspection, and third-party lab results included with every shipment.

- Customer Feedback: Over 97% satisfaction rated by OEM/plant engineers across three continents (internal MiningZY report, 2024).

- "Improved Design and Life of Pump Liners: Industry Case Studies" – Eng-Tips Industrial Pump Forum

- "Wear Resistance of Cast Iron Slurry Pump Liners" – Materials & Design, Elsevier, 2024

- "ISO 21940-23: Mechanical Vibration—Pump Component Specification" – iso.org

- "Slurry pump wear parts alternatives & innovations" – Min-Ex Industry News

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025