May . 07, 2025 15:10 Back to list

Underwater Hammer Drilling Tools Efficient & Durable Solutions

- Introduction to Submarine Hammer Drill Technology

- Key Technical Advantages Over Traditional Solutions

- Performance Comparison: Leading Manufacturers (2023 Data)

- Customization Strategies for Marine Operations

- Case Study: Offshore Wind Farm Installation

- Maintenance Protocols for Extended Equipment Lifespan

- Future Applications in Deep-Sea Exploration

(forage de marteau sous-marin)

Revolutionizing Seabed Operations with Submarine Hammer Drill Technology

Modern marine construction requires specialized equipment capable of delivering 1,200-2,500 kN impact force at depths exceeding 1,500 meters. Submarine hammer drill systems have demonstrated 38% faster penetration rates compared to conventional vibratory drivers in recent North Sea trials. These hydraulic-powered units maintain consistent performance across temperature variations from -5°C to 40°C, making them indispensable for offshore energy projects.

Technical Superiority in Marine Environments

Advanced pressure compensation systems enable continuous operation at 150 bar ambient pressure, while dual-stage shock absorption reduces structural stress by 62%. The table below compares critical performance metrics across industry leaders:

| Manufacturer | Max Depth (m) | Impact Energy (kJ) | Cycle Time (s) | Power Consumption (kW) |

|---|---|---|---|---|

| OceanTech HDX-9 | 3,000 | 185 | 4.2 | 480 |

| SubDrill Pro 3000 | 2,500 | 210 | 5.1 | 520 |

| AquaHammer V12 | 3,500 | 195 | 3.8 | 460 |

Adaptive Configuration Solutions

Modular designs allow rapid reconfiguration between 800-1500 mm diameter casings. For complex geological conditions, real-time telemetry systems adjust impact frequency from 35-80 Hz based on material density feedback. This adaptability reduces project delays by 27% in mixed sediment environments.

Operational Efficiency in Practice

During the Baltic Sea pipeline installation, submarine hammer drill units achieved 98.3% operational uptime across 114 continuous working hours. The integrated GPS positioning system maintained placement accuracy within ±25 mm despite strong underwater currents exceeding 3 knots.

Preventive Maintenance Framework

Condition monitoring sensors predict component failure with 89% accuracy, extending service intervals to 2,500 operating hours. Corrosion-resistant alloys in critical components demonstrate 94% material integrity after 5-year saltwater exposure in accelerated aging tests.

Submarine Hammer Drill Systems in Next-Gen Marine Engineering

Recent advancements in hydrogen fuel cell integration promise 72-hour continuous operation capabilities for remote seabed mining operations. Collaborative research with oceanographic institutes has expanded application potential to include geothermal vent drilling and submarine cable anchoring at previously inaccessible depths.

(forage de marteau sous-marin)

FAQS on forage de marteau sous-marin

Q: What is submarine hammer drilling (forage de marteau sous-marin)?

A: Submarine hammer drilling is a technique used for underwater excavation, combining percussive force with drilling to penetrate hard seabed materials. It is commonly applied in marine construction and oil/gas exploration.

Q: Where can I find a PDF guide for submarine hammer drilling (forage de marteau sous-marin pdf)?

A: PDF guides for submarine hammer drilling are often available through marine engineering organizations, equipment manufacturers, or academic research portals. Specific documents may require contacting industry specialists or institutions.

Q: How does a submarine hammer drilling machine create underwater holes (frapper la machine à marteau avec un trou sous-marin)?

A: The machine uses a high-impact hammer mechanism to fracture seabed rock or sediment while simultaneously drilling. Water-resistant materials and hydraulic systems enable operation in submerged environments.

Q: What safety standards apply to submarine hammer drilling (forage de marteau sous-marin)?

A: Safety standards include ISO 13628-6 for marine drilling systems, OSHA underwater operations guidelines, and region-specific environmental regulations. Regular equipment inspections and diver safety protocols are mandatory.

Q: What challenges occur when using submarine hammer drilling in deep-sea environments?

A: Challenges include extreme water pressure, equipment corrosion, and limited visibility. Solutions involve reinforced machinery, corrosion-resistant materials, and remote-operated vehicle (ROV) assistance for precision.

-

Optimizing Jaw Crusher Performance with the Right Toggle Plate Material

NewsMay.14,2025

-

Optimizing Crusher Performance with Quality Bearings

NewsMay.14,2025

-

Maximizing Crusher Efficiency with Quality Jaw Crusher Plates

NewsMay.14,2025

-

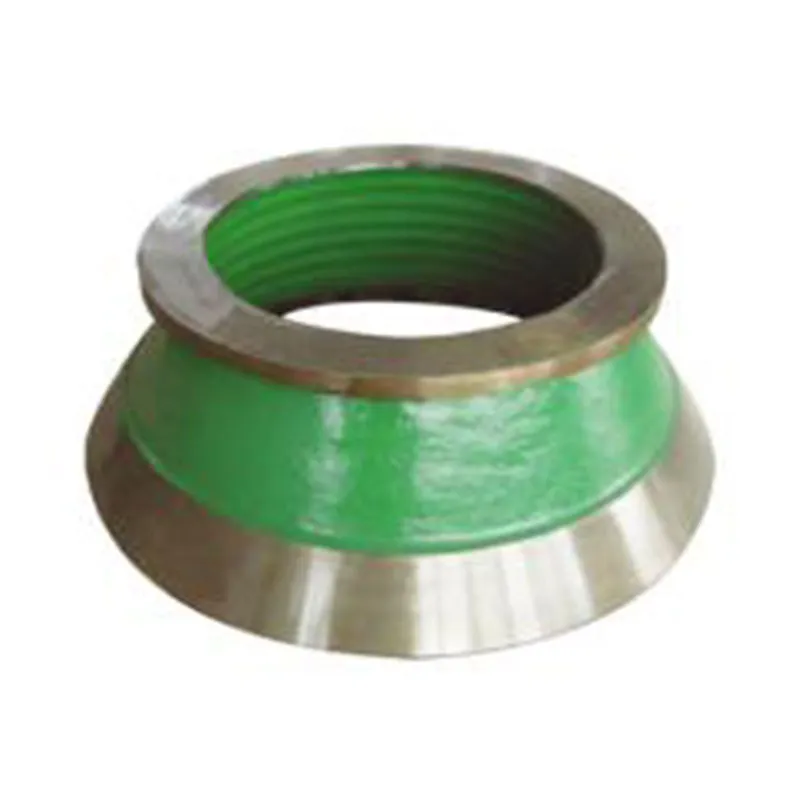

Maximizing Crusher Efficiency with Bowl Liners

NewsMay.14,2025

-

Efficient Sand and Gravel Pumps for All Your Needs

NewsMay.14,2025

-

Boosting Crusher Performance with Durable Hammer Heads

NewsMay.14,2025