- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jul . 31, 2025 06:40 Back to list

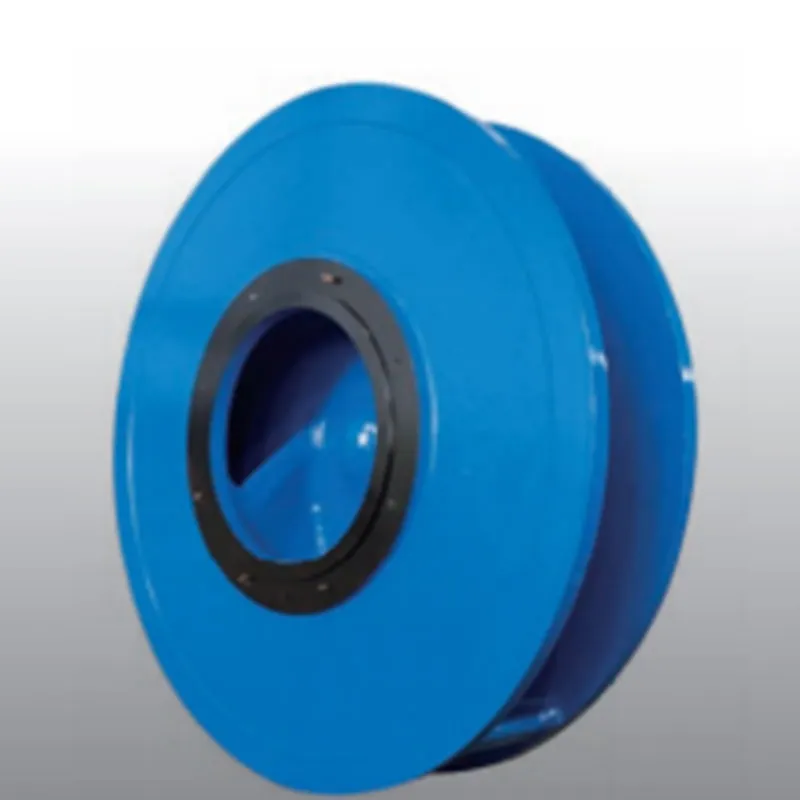

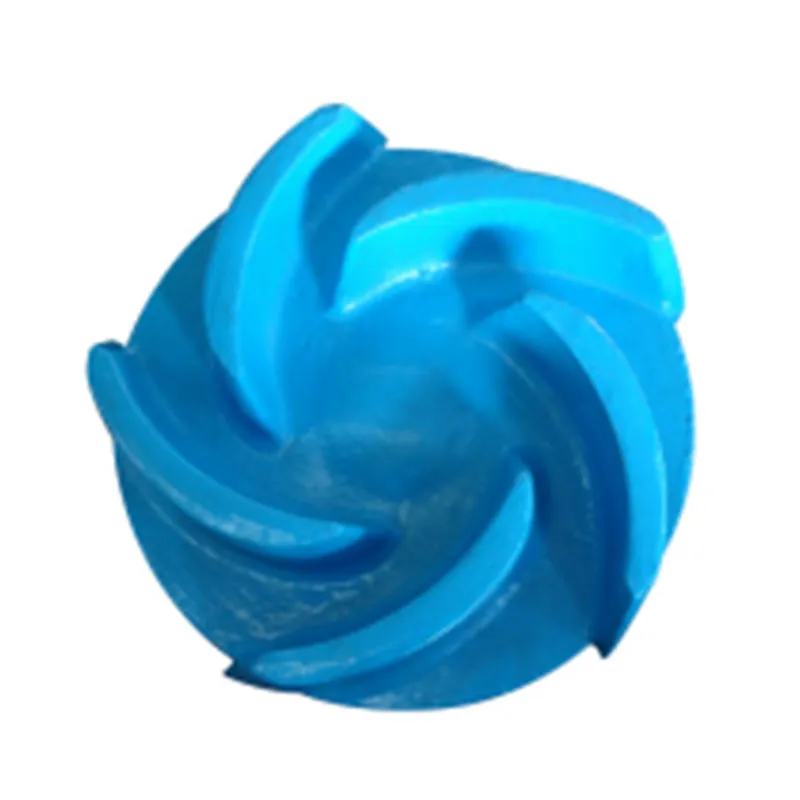

Durable Slurry Pump Impeller for High-Efficiency Abrasive Handling

Explore the core of slurry transport technology—slurry pump impeller. Discover key features, material science, manufacturing processes, industry data, authoritative certifications, vendor comparisons, customizations, and real-world applications. Everything an engineer, buyer, or project lead must know in 2024.

Industry Overview & Technical Terminology

Key Terms Explained

- Impeller: Rotating element that imparts kinetic energy to slurry.

- Slurry: Mixture of solids & liquids, often highly abrasive.

- Volute: The casing that collects discharge from the impeller.

- Hardness (HRC): Material’s resistance to abrasion—critical for wear life.

- Efficiency (%): Ratio of hydraulic energy delivered to input energy.

- Shroud: Plates defining impeller's outer boundaries; closed or open types.

- Bearing Assembly: Mechanism that supports the rotating impeller shaft.

Market Trends (2024)

- Global slurry pump market CAGR (2021-2027): 5.5%

- Wear-resistant alloys (High Chrome, Duplex SS) >60% of new installations

- Increasing demand in lithium, nickel, rare earth, tailings reprocessing

- Efficiency optimization & digital monitoring integration on the rise

Product Overview: Impeller

Our flagship slurry pump impeller is engineered for extreme duty: offering advanced anti-abrasive performance, customization flexibility, and compliance with top industry standards. Backed by global clients in mining, metallurgy, chemicals, and municipal sectors.

Key Specifications

| Type | Diameter (mm) | Material | Max Solid Size (mm) | Efficiency (%) | Standard |

|---|---|---|---|---|---|

| Closed Slurry Impeller | 260 - 865 | High Chrome Alloy (A05/HCr) | 15 - 85 | 56-74 | ISO 5199, ANSI B73.1 |

| Semi-Open Sludge Pump Impeller | 180 - 730 | Rubber Lined / Polyurethane | 40 - 75 | 62-71 | ISO 9906 |

| Open Impeller Slurry Pump | 110 - 530 | Duplex Stainless Steel | 18 - 58 | 65-73 | EN 25199 |

| Recessed Vortex | 200 - 680 | Special Alloy/Custom | max 120 | 51-62 | API 610 |

Manufacturing Process of Slurry Pump Impeller

Industry Quote: “Correct material and precise hydro-profiles reduce energy cost per tons slurried by up to 18%.” (Pumps & Systems Journal, 2024)

Material & Design Advantages

- High Chrome Alloy (A05, A49): Up to 5x the abrasion resistance of standard cast iron; optimal microstructure for mineral processing.

- Duplex Stainless Steel: Superior pitting resistance & longevity for brine, chemical, or seawater applications.

- Polyurethane / Rubber Linings: Sludge pump impeller optimized for fine/soft suspended solids and corrosive lightweight slurry.

- Closed vs. Open Design: Closed for high-efficiency transfer of fine solids, open/recessed for large particle or fibrous fluids.

- Dynamic Balancing: Every slurry pump impeller is balanced to ISO 1940 G6.3 or better — ensures vibration-free, longer bearing life.

- Available Certifications: ISO 5199, ISO 9906, EN 25199, API 610/674. Full MTR (material test report) with each batch.

Slurry Pump Impeller Price & Vendor Comparison

| Manufacturer | Country | Material Option | Price (USD FOB, 2024) | Certifications | Lead Time (days) |

|---|---|---|---|---|---|

| ZY Mining (Official) | China | A05, A49, DSS, PU, Rubber | 135 – 1,950 | ISO, ANSI, SGS | 12–35 |

| Weir Minerals | UK | HC Alloy, Metal, Rubber | 180 – 3,400 | ISO, API | 15–45 |

| KSB | Germany | DSS, Chrome Alloy, PU | 280 – 2,900 | ISO, EN | 18–42 |

| Metso Outotec | Finland | HC Alloy, Rubber | 215 – 3,200 | ISO, GOST | 19–51 |

Note: Slurry pump impeller price varies with diameter, material, and application complexity; discounts available for OEM/quantity orders.

Custom Solutions for Your Slurry Application

Engineering teams often require bespoke slurry pump impeller solutions—accounting for slurry particle size, pH, specific gravity, operating hours, and installation standards (ISO 2858, ANSI B73.1).

- Custom Geometry: Variable vane angle, optimized shroud, channel width for minimizing wear in high-impact zones.

- Material Engineering: For acid, brine, or phosphate—duplex/PU; for iron/copper/mine tailings—A05/A49.

- Sealing & Surface Treatment: Epoxy or PTFE for aggressive or high-cl content; rubber for soft solids.

- Testing & Certification: Witnessed hydraulic trials, run-to-failure tests—full traceability for regulatory (EPA, MSHA, GOST-R) demands.

Application Scenarios

Using A05 closed impeller slurry pump (Ø510mm), site increased scheduled uptime from 640h to 940h/inspection, slurry pump impeller wear reduced by 37%.

Service Case Studies & Customer Feedback

— Process Manager, Asia Salt Chemicals, 2023

— Maintenance Supervisor, Russian Mining & Metallurgy, 2022

— Facilities Engineer, South American Gold Mine, 2024

Slurry Pump Impeller Technical FAQ

Delivery, Warranty, & Support

- Typical Delivery Cycle: 10–35 days (ex-factory), includes full test records, photo/video documentation, and QR traceability label.

- Warranty: 15–24 months against material/manufacture defects.

- Documentation: MTRs, compliance codes, NDT/QC docs, hydraulic performance curve included.

- Support: Global partners in 12 countries, with emergency stock available for fast-track projects.

- OEM/ODM: Can produce per client drawing, logo, surface color, or case marking.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025