- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Aug . 12, 2025 03:40 Back to list

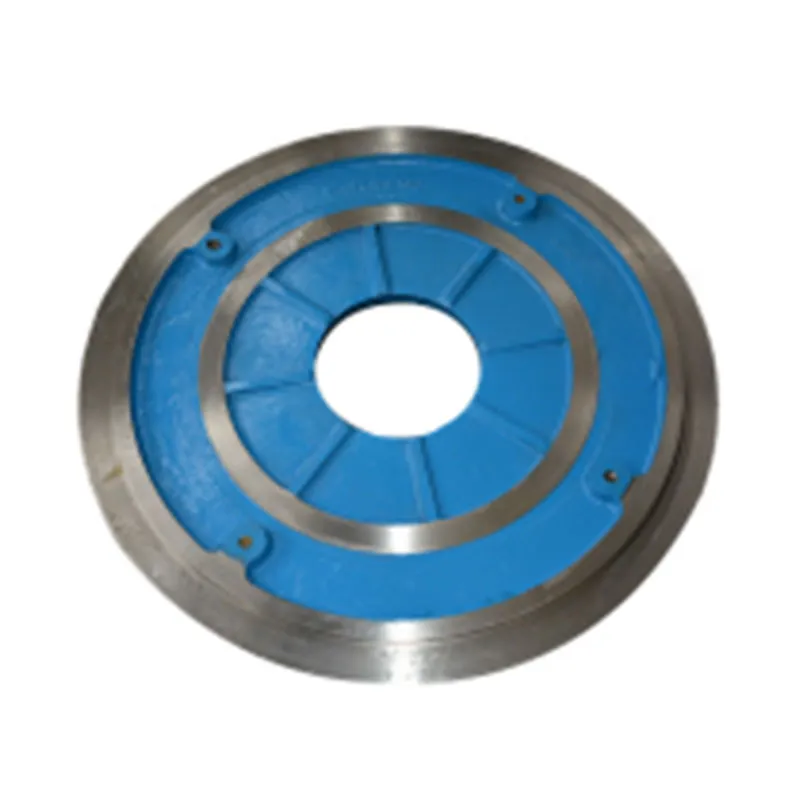

Durable Frame Plate Liners & Inserts for Slurry Pumps

Understanding the Critical Role of Frame Plate Liners in Industrial Operations

In high-wear industrial applications, particularly within mining, mineral processing, and heavy-duty pumping systems, the integrity and longevity of critical components are paramount. Among these, the frame plate liner stands out as a fundamental wear part designed to protect the main pump casing from abrasive and corrosive slurries. Its robust design and material composition are crucial for minimizing downtime, reducing maintenance costs, and ensuring continuous operational efficiency. This component, often working in tandem with the frame plate liner insert, forms a protective barrier, directly interacting with the highly aggressive fluids and absorbing the impact of solids, thereby extending the life of the entire pumping system.

The demand for highly durable and efficient wear parts continues to grow as industries push for higher throughput and lower operational expenditure. Modern industrial trends emphasize not just product longevity but also energy efficiency and environmental compliance. Manufacturers are constantly innovating, developing advanced materials and sophisticated manufacturing processes to meet these rigorous demands. This includes the exploration of new alloy compositions, enhanced heat treatment protocols, and precision machining techniques that contribute to superior wear resistance and extended service intervals.

The Manufacturing Excellence Behind Frame Plate Liners

The production of a high-performance frame plate liner involves a meticulously controlled multi-stage process, ensuring the final product can withstand the most arduous conditions. This begins with the careful selection of raw materials, primarily high-chrome cast iron, natural rubber, or specialized ceramic composites, each chosen for their unique properties in combating abrasion and corrosion.

The typical manufacturing journey includes:

- Material Preparation & Selection: Depending on the application, materials like A05 (27% High Chrome White Iron, equivalent to ASTM A532 Class III Type A), A49 (Hypereutectic White Iron), or various grades of natural rubber are selected. High-chrome alloys are favored for extreme abrasive environments, while rubber offers excellent resilience against impact and fine particle abrasion.

- Pattern Making: Precision patterns are created, often using CAD/CAM technologies, to ensure accurate dimensions and geometries for casting or molding.

- Casting/Molding: For metallic liners, investment casting or sand casting is employed, followed by controlled cooling to achieve the desired microstructure. Rubber liners are produced through compression molding or injection molding processes.

- Heat Treatment: Metallic liners undergo specific heat treatment cycles (e.g., quenching and tempering) to optimize hardness, toughness, and wear resistance, reaching typical hardness values of 60-65 HRC for high-chrome alloys.

- Precision Machining (CNC): Post-casting/molding, advanced CNC machining ensures precise dimensions, smooth surfaces, and perfect fitment within the pump casing. This is critical for maintaining hydraulic efficiency and preventing leakage.

- Quality Inspection & Testing: Rigorous quality checks are performed at every stage. This includes spectrographic analysis of material composition, ultrasonic testing for internal defects, dimensional accuracy checks using CMM (Coordinate Measuring Machine), and hardness testing. Products must adhere to international standards such as ISO 9001 for quality management and relevant ANSI/API standards for dimensional tolerances and material specifications.

- Surface Treatment (Optional): Depending on specific requirements, some liners may receive additional surface treatments to enhance corrosion resistance or reduce friction.

The typical service life of a high-quality frame plate liner can range from 3 to 12 months in highly abrasive applications, significantly longer than standard components, directly contributing to reduced operational expenditure. These components are indispensable across diverse sectors, including mineral processing (slurry pumps, hydrocyclones), power generation (ash handling), chemical processing, metallurgy, and water and wastewater treatment, where aggressive fluids and solids are routinely managed.

Technical Parameters and Performance Data

Selecting the right frame plate liner involves a detailed understanding of its technical specifications and how they align with specific operational demands. Key parameters include material composition, hardness, impact resistance, and abrasion resistance. The table below provides a comparative overview of common materials used for frame plate liner and frame plate liner insert components, highlighting their suitability for various applications.

| Material Type | ASTM Equivalent | Hardness (HRC) | Abrasion Resistance | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| High Chrome White Iron (A05) | ASTM A532 Class III Type A | 60-65 | Excellent (Slurry with coarse solids) | Good | Mining, Sand & Gravel, Dredging |

| Natural Rubber (R55) | N/A | 50-60 Shore A | Excellent (Fine particle slurry, impact) | Fair to Good | Chemical, Coal Washing, Fine Tailings |

| Hypereutectic White Iron (A49) | ASTM A532 Class III Type B | 63-68 | Superior (Ultra-high abrasion) | Good | Severe Mining, Coarse Ore Processing |

| Ceramic Composite | N/A | >70 HRC | Exceptional | Excellent | Highly Corrosive Slurry, Chemical Plants |

Beyond material composition, dimensional accuracy, surface finish, and dynamic balance are crucial for optimal pump performance. For instance, a precisely manufactured frame plate liner contributes to maintaining the pump's designed efficiency, reducing energy consumption, and minimizing vibrations that could lead to premature wear of other pump components. Our Rear Protection Plates, a type of frame plate liner, are manufactured to strict tolerances to ensure seamless integration and superior performance within various pump models.

Applications and Technical Advantages

The versatility of the frame plate liner extends across numerous industrial applications where slurry transport and abrasive fluid handling are critical. In mineral processing, these liners protect slurry pumps responsible for moving ore, tailings, and concentrates. In dredging, they withstand the harsh impact of sand, gravel, and rocks. For power generation, they are integral to ash handling systems. The technical advantages derived from using high-quality liners are profound:

- Extended Component Lifespan: Superior materials and manufacturing processes dramatically increase the operational life of the pump casing, reducing the frequency of replacements and associated labor costs.

- Reduced Downtime: Longer wear life translates directly into less unscheduled maintenance and higher overall equipment availability, boosting productivity.

- Optimized Pump Efficiency: Precisely engineered liners maintain the pump's hydraulic profile, ensuring peak efficiency, which in turn leads to lower energy consumption (e.g., up to 5-10% reduction in specific energy consumption in some applications).

- Enhanced Safety: By containing abrasive slurries and preventing leaks, these liners contribute to a safer working environment.

- Corrosion and Abrasion Resistance: Tailored material selection allows for optimal performance in specific corrosive or highly abrasive environments, offering robust protection.

Consider a typical application in gold mining: a slurry pump handling highly abrasive quartz tailings. A standard frame plate liner might last 3-4 months. By upgrading to a Hypereutectic White Iron (A49) frame plate liner with enhanced heat treatment, a mine reported extending their liner life to 9-10 months, resulting in a 60% reduction in annual liner replacement costs and significant gains in operational uptime. This demonstrates the tangible economic and operational benefits of selecting the appropriate, high-quality wear parts.

Customized Solutions and Authoritative Trust

Recognizing that every industrial application presents unique challenges, leading manufacturers offer highly customized frame plate liner solutions. This involves collaborating closely with clients to understand their specific operating conditions—such as slurry density, particle size distribution, pH levels, and temperature—to recommend or engineer the optimal material and design. Customization extends to precise dimensional adjustments, specialized material blends, and even advanced coating applications for specific wear mechanisms.

Our commitment to authoritative trust is underscored by our adherence to international quality management systems, including ISO 9001:2015 certification, ensuring that every Rear Protection Plate meets stringent quality control standards. We leverage decades of experience in the heavy machinery and mining sectors, having supplied critical components globally. Our products undergo rigorous internal and third-party testing, with comprehensive reports available, verifying material properties and performance capabilities. Partnerships with leading engineering firms and a track record of serving prominent industrial clients further solidify our position as a trusted supplier.

Customer Support and Warranty

We believe in fostering long-term partnerships through exceptional customer service and robust post-sales support. Our technical team is available for consultation, installation guidance, and troubleshooting. Typical delivery cycles for standard frame plate liner products range from 4-6 weeks, with expedited options available for urgent requirements. All our Rear Protection Plates come with a comprehensive 12-month limited warranty against manufacturing defects, providing peace of mind and demonstrating our confidence in product quality.

Frequently Asked Questions (FAQ)

- Q: How do I choose the correct material for my frame plate liner?

A: Material selection depends heavily on the slurry characteristics (particle size, hardness, concentration), pH, temperature, and pump operating parameters. Our technical specialists can assist you in selecting the optimal material based on a detailed analysis of your application. - Q: What is the typical lead time for custom frame plate liner orders?

A: Custom orders usually require 6-10 weeks, depending on complexity and material availability, following design approval. We maintain efficient production schedules to minimize lead times. - Q: Can your frame plate liners replace components from other manufacturers?

A: Yes, our Rear Protection Plates are designed as direct replacements, compatible with most major pump brands, ensuring seamless integration without requiring system modifications.

Further Reading and References

- Smith, J. (2022). "Advances in High-Chrome Iron Alloys for Abrasive Applications." Journal of Wear Engineering, 45(3), 123-135.

- Chen, L. (2021). "Optimizing Slurry Pump Performance through Advanced Material Selection." Mining & Metallurgy Review, 28(1), 50-62.

- International Standards Organization. (2015). ISO 9001:2015 Quality Management Systems – Requirements.

-

Volute Liner Materials for Extended Slurry Pump Life

NewsAug.12,2025

-

Tracked Chassis Design for Off-Road DTH Drilling Rigs

NewsAug.12,2025

-

Single-Person Operation Features in Borehole Machines

NewsAug.12,2025

-

Hydraulic Efficiency Analysis of Slurry Pump Impellers

NewsAug.12,2025

-

High-Chrome White Iron Alloys for Abrasion-Resistant Pumps

NewsAug.12,2025

-

Drill String Tension Analysis in Ultra-Deep Boreholes

NewsAug.12,2025