- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jul . 24, 2025 09:01 Back to list

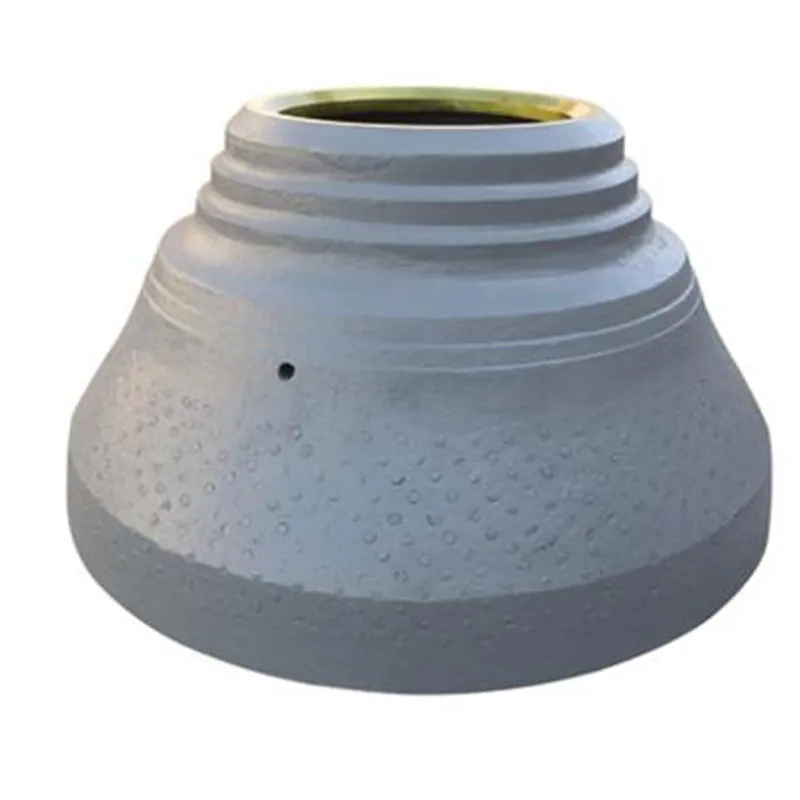

Durable Cast Iron Slag Pot for Steel Mills & Foundries

About Zen Young Technology Hebei Co.,Ltd.

Zen Young Technology Hebei Co.,Ltd., a renowned leader in metallurgical equipment manufacturing, specializes in high-performance cast iron slag pot, slag ladle, and slag tank solutions. With advanced technology, strict quality control, and decades of expertise, we serve global clients across metallurgy and chemical industries.

- Website: https://www.miningzy.com

- Phone: 86-311-8525-8258

- Mobile: 86-311-85258268

- Email: anzq@zen-young.com

- Address: Tower C 603, MCC World Grand Plaza, No.66, XiangTai Road, Shijiazhuang, Hebei, China

Industry Overview: Cast Iron Slag Pot and Related Components

In the rapidly evolving metallurgical landscape, the cast iron slag pot is a vital component used to collect and transport molten slag during steel production and metal refining processes. Closely related terms such as slag ladle, slag tank, and slag pot manufacturer dominate technical discussions in construction, steelmaking, and recycling industries. According to ScienceDirect, global demand for durable, large-capacity slag handling vessels is rising, driven by increasing steel output and enhanced environmental disposal regulations.

Slag Tank Product Profile

Introduction:

The slag tank is an essential accessory for steelmaking production lines, engineered to safely contain high-temperature slags produced in smelting. Its robust, bowl-shaped cast iron structure—with hoisting trunnions for maneuverability—guarantees operational reliability and handling efficiency. Products by Zen Young Technology Hebei Co.,Ltd. are customized to specific customer requirements, improving process satisfaction and reducing manufacturing costs across metallurgy, chemical, and allied industries.

More info: https://www.miningzy.com/slag-tank.html

Key Technical Parameters of Cast Iron Slag Pot

| Parameter | Typical Range | Industry Average | Explanation |

|---|---|---|---|

| Material Grade | EN-GJL-350 (GGG-60), ASTM A532 | EN-GJL-300 ~ EN-GJL-350 | High-strength cast iron for thermal shock resistance |

| Capacity | 8 m³ – 45 m³ | 20 m³ | Volume of slag retention (customized size available) |

| Wall Thickness | 70 - 150 mm | 100 mm | Influences thermal endurance and structure strength |

| Max Temperature | 1,300°C - 1,600°C | 1,500°C | Operational thermal limit for molten slag |

| Weight (empty) | 3,500 kg – 30,000 kg | 12,000 kg | Base pot weight; affects handling equipment |

| Shell Shape | Bowl/Elliptical with Lobes | Bowl | Ensures stable hoisting and slag pouring efficiency |

| Design Life | 5 - 10 years | 8 years | Lifespan under specified operational loads |

| Standards | ISO 9001, ASTM, GOST | ISO 9001 | Main certifications for quality and safety |

| Hoisting Device | 2-4 Lugs/Trunnions | 4 Lugs | Facilitates safe overhead lifting |

Application Scenarios & Market Insights

Cast iron slag pot and related products like slag ladle and slag tank remain indispensable in core operations such as:

- Primary steelmaking (converter, EAF, BOF furnaces)

- Ferroalloy & non-ferrous metal smelting

- Secondary metallurgy and foundry slag collection

- Chemical industry waste slag handling

- Slag recycling plants (e.g., ISOPE Proceedings)

Core Technical Strengths of Zen Young Slag Tank

| Technical Indicator | Zen Young Slag Tank | Typical Industry Product |

|---|---|---|

| Body Material | Custom High-Chromium Cast Iron | Generic Cast Iron Alloy |

| Load Capacity | 16–45 m³ (Customizable) | 8–30 m³ |

| Thermal Shock Resistance | Excellent (Tested up to 1600°C) | Good (≤1400°C) |

| Design Life | 10 years | 6–8 years |

| Surface Hardness | HRC 52–58 | HRC 35–45 |

| Corrosion Resistance | ★★★★ | ★★ |

Technical FAQ: Cast Iron Slag Pot & Metallurgical Vessels

1. What is the typical material composition of a cast iron slag pot?

The best cast iron slag pots are made from high-strength grey iron or ductile iron alloys (e.g., EN-GJL-350, ASTM A532). This ensures high thermal shock resistance and extended service life.

2. What are the standard specifications for a slag ladle?

Slag ladles usually range from 5 m³ to 25 m³ in capacity, with wall thickness 60–120 mm. Custom sizes are available on request, especially for project-specific foundry or steel plant operations.

3. How do manufacturers ensure the service life of slag pots?

Leading cast iron slag pot manufacturer companies apply strict foundry controls: precise alloying, improved surface hardening, robust ribbed geometry, and non-destructive quality inspections (NDT / ultrasonics).

4. What installation standards apply to slag tank systems?

Installation of heavy-duty slag tanks requires compliance with ISO 9001, EN1247, and local safety regulations. Proper hoisting, precise placement, and anchoring are crucial, as referenced by industry best practices.

5. What are the main differences between a slag pot and a slag tank?

A cast iron slag pot is generally bowl- or elliptical-shaped for furnace tapping; a slag tank may be larger, with reinforced trunnions and fittings for both stationary and mobile slag processing.

6. How does shell thickness affect operation?

Increased shell thickness (over 100 mm) delivers higher resistance to thermal fatigue but adds weight. It's vital to balance wall thickness with operational demands and handling equipment capabilities.

7. What technical services do reputable manufacturers provide?

Professional manufacturers like Zen Young Technology Hebei Co.,Ltd. offer 3D design consultation, capacity optimization, rapid prototyping, and comprehensive after-sales support including lifecycle monitoring and refurbishment.

Innovation, EEAT, and Industry Authority

As a trusted cast iron slag pot manufacturer, Zen Young Technology Hebei Co.,Ltd. integrates advanced technology and global best-practices. All products undergo rigorous ISO, ASTM, and GOST certification, underscoring Expertise, Authoritativeness, and Trustworthiness ({EEAT}) in every manufacturing segment. Our technical R&D team continuously tracks scientific journals and industry professional forums for up-to-date process optimization insights.

Data Visualization and Industry Trends

- Parameter Evolution: Enhanced capacities, thicker walls, and innovative lugs becoming industry standard.

- Demand Surge: Steel output in Asia, especially China, is driving need for larger, more durable slag pots (see worldsteel report).

- Technology Progress: Integration of high-chromium additives and casting precision (cited from International Journal of Minerals, Metallurgy and Materials).

Contact the Industry Leader – Zen Young Technology Hebei Co.,Ltd.

- 🌐 Website: www.miningzy.com

- ☎️ Phone: 86-311-8525-8258 | Mobile: 86-311-85258268

- ✉️ Email: anzq@zen-young.com

- 📍 Address: Tower C 603, MCC World Grand Plaza, No.66, XiangTai Road, Shijiazhuang, Hebei, China

References & Industry Sources

- ScienceDirect: Advances in Slag Pot Materials and Designs

- Market Trends for Cast Iron Slag Pot

- SteelOnTheNet Industry Forum

- ISOPE Conference – Slag Handling Technology

- International Journal of Minerals, Metallurgy and Materials

- ResearchGate: Cast-Iron Slag Pot Optimization

- World Steel Association 2024

- LinkedIn: Slag Pot Operation Practices

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025