- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 02, 2025 04:33 Back to list

dth hammer bit price

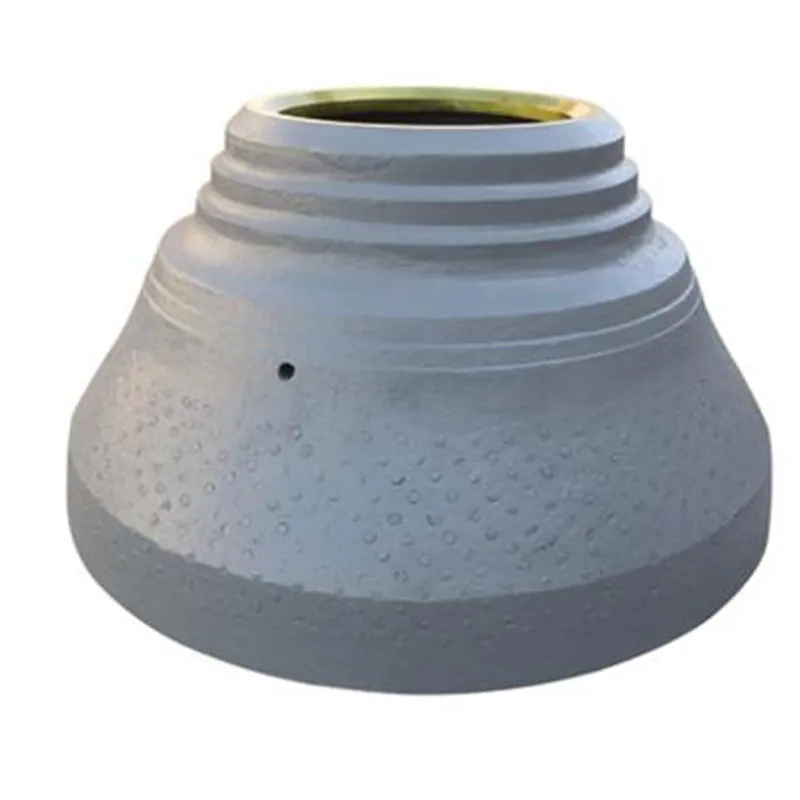

Brand reputation cannot be overlooked when considering hammer bit prices. Renowned manufacturers, known for consistent quality and after-sales support, typically price their products above lesser-known brands. Trust in brand reliability often justifies the higher price for many experienced buyers, who value long-term partnership potential and the assurance of defect-free products. Drilling conditions and specific project requirements also play a significant role in selecting the appropriate hammer bit and thus influencing its price. It's crucial to analyze the geological conditions and choose a bit that performs efficiently in those settings. Experts often advise consulting with manufacturers who can offer tailored solutions based on the specific characteristics of the drilling environment. This expertise not only helps in selecting the right tool but also ensures that the investment aligns with the project's demands. In reviews and feedback from industry professionals, it's evident that investing in the right hammer bit can make a significant difference in operational efficiency and cost-effectiveness. Trustworthy insights from those who have extensive field experience underscore the importance of evaluating the total cost of ownership rather than just the upfront price. This approach considers factors like durability, performance, and potential downtime costs, offering a more holistic view of value. In conclusion, the price of DTH hammer bits is shaped by an interplay of material quality, design sophistication, manufacturing processes, brand prestige, and application specifics. By leveraging experience and expertise, and weighing authoritativeness and trustworthiness, decision-makers can choose hammer bits that not only meet their drilling requirements but also offer optimal cost-efficiency. For those striving in sectors demanding precision and reliability such as mining, construction, and geothermal drilling, comprehending these dynamics is essential to achieve project success.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025