- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 25, 2025 01:22 Back to list

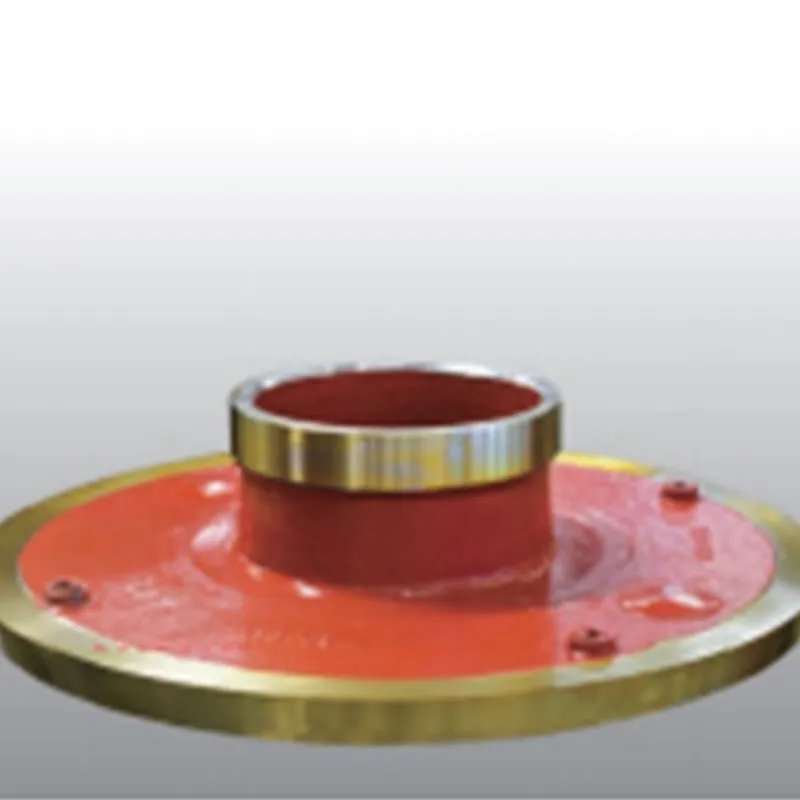

dth hammer assembly

Authority in the domain of DTH hammer assemblies can be attributed to leading manufacturers and engineers who continuously innovate to improve performance. These experts often engage in rigorous testing and refinement processes, ensuring that the assemblies can endure intense operational demands. They contribute to the field by publishing their findings and innovations, sharing insight into new material compositions and design improvements that set industry standards. Trustworthiness in the use of DTH hammer assemblies is established through high-quality manufacturing and rigorous quality assurance processes. Renowned manufacturers are ISO certified, adhering to strict standards that guarantee the consistency and safety of their products. This trust is earned through decades of field-proven reliability, often supported by comprehensive warranties and customer service that addresses issues promptly. The interplay of these factors—experience, expertise, authoritativeness, and trustworthiness—culminates in a product that is indispensable to drilling operations across various sectors. Those considering investing in DTH hammer assemblies will find value in this holistic view. By choosing a reputable supplier and gaining insights from seasoned professionals, operators can make informed decisions that optimize their operations both in terms of performance and cost-efficiency. In conclusion, the DTH hammer assembly is not merely a tool, but a carefully engineered solution that embodies the pinnacle of drilling technology. It stands as a testament to the innovative spirit of the industry, backed by real-world performance and reliable craftsmanship. Whether employed in subterranean explorations or infrastructure development, these assemblies ensure that the project is as seamless and efficient as technology allows.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025