- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 24, 2025 03:09 Back to list

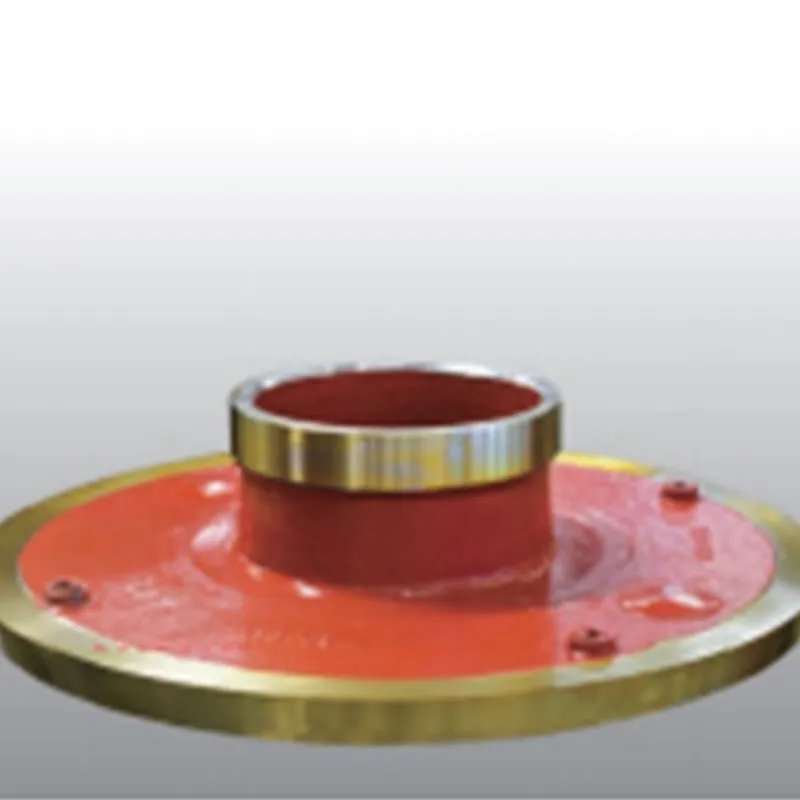

down the hole drilling tools

The expertise required to effectively employ DTH drilling tools cannot be overstated. Training for operation is essential; seasoned operators understand the dynamics of handling these powerful tools, thus ensuring the precision and quality of the drilling operations. Manufacturers often provide detailed manuals and training programs, equipping operators with the necessary skills to maximize the tools’ capabilities. Adequate training reduces wear and tear and increases safety, especially in challenging environments. Authoritative practices in DTH drilling also involve adhering to strict environmental and safety regulations. The implementation of eco-friendly lubricants and biodegradable additives is a growing trend aiming to minimize the ecological impact of drilling activities. Companies like Sandvik are at the forefront of developing such sustainable practices, ensuring that their DTH products not only meet the industry standards for performance but also contribute to reducing the carbon footprint of drilling operations. Trustworthiness in the DTH tool industry is often built on the foundation of post-purchase support and service. Reliable after-sales service ensures that any operational hiccups are swiftly addressed, minimizing potential downtimes. Boart Longyear, for instance, offers comprehensive support and maintenance programs that include training sessions, equipment upgrades, and quick response repair services. Such dependable support enhances the operational lifespan of the equipment and establishes a firm trust in the manufacturer's commitment to client success. In summary, down the hole drilling tools are indispensable in modern drilling operations, demanding a precise balance of cutting-edge technology and user expertise. As the industry progresses, the focus on customization, sustainability, and operator training will continue to shape the effectiveness of DTH drilling tools. Embracing these advances not only elevates operational performance but also fortifies the position of manufacturers as leaders in providing reliable and efficient drilling solutions.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025