- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Jan . 24, 2025 03:55 Back to list

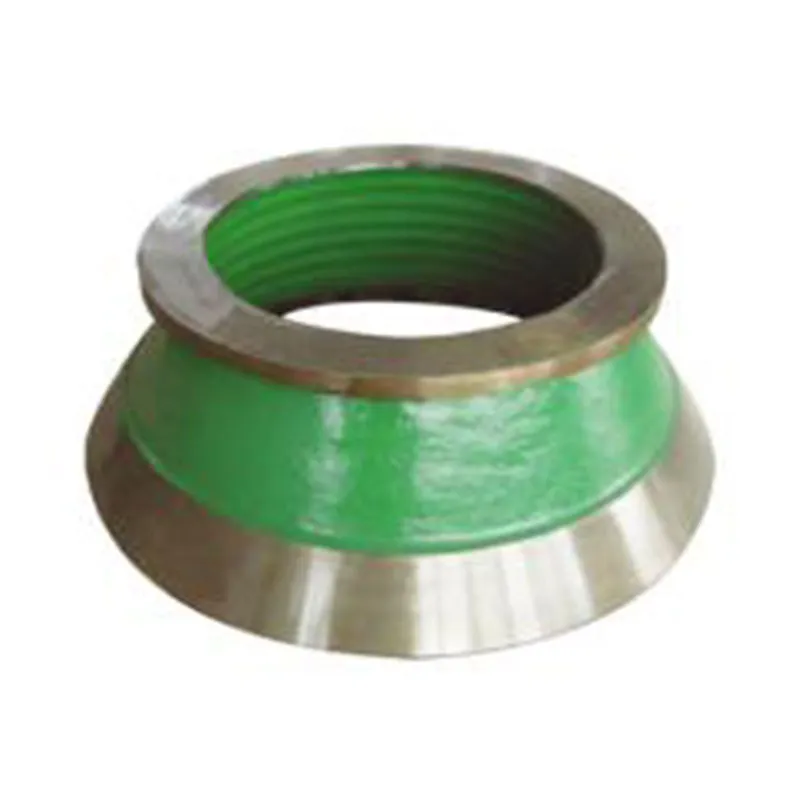

downhole drilling equipment

Given the critical nature and complexity of downhole drilling equipment, expertise in this field cannot be overstated. Skilled engineers and field operators must possess not only technical knowledge but also experience in handling equipment failures and unexpected geological conditions. Continuous training and upskilling are vital for the workforce to keep pace with technological advancements and ensure safety and efficiency in operations. Moreover, industry standards and regulatory oversight provide a framework that guarantees quality and safety in downhole drilling equipment. Organizations such as the American Petroleum Institute (API) set forth guidelines that manufacturers and operators must follow to ensure equipment performance meets rigorous demands. Adherence to these standards not only grants credibility to manufacturers but also builds trust with oil and gas companies seeking reliable equipment solutions. From a trustworthiness perspective, partnerships between drilling companies and equipment manufacturers play a crucial role. Manufacturers often offer specialized training and support services to their clients, fostering long-term relationships based on reliability and performance assurance. By choosing reputable equipment providers, drilling companies can mitigate risks and drive efficiencies in their operations. For those in the oil and gas industry, embracing the intricacies of downhole drilling equipment correlates directly with operational success. As technology continues to advance, the emphasis on integrating comprehensive expertise, leveraging innovative technologies, and adhering to set standards will remain at the forefront of industry practices. Ultimately, the right balance of expertise and technology is crucial for overcoming the challenges of modern drilling operations, enhancing productivity, and safeguarding environmental resources.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025