- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 19, 2025 03:59 Back to list

rock auger bullet teeth

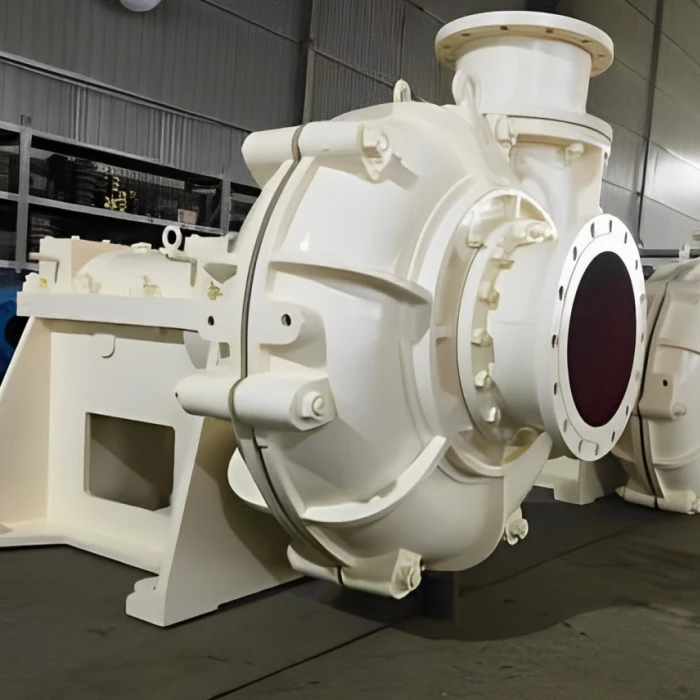

With authority comes the insight that regulations and industry standards must be adhered to when selecting and maintaining pump components. Compliant pump covers not only help in maintaining operational efficiency but also fulfill safety requirements crucial for both the workforce and the environment. A compliance officer from a leading global construction firm shared that using certified components significantly reduces risks associated with environmental spills and personnel hazards. Trust in the quality and durability of a pump cover derives from rigorous testing and industry certifications. It's enlightening to note that manufacturers who provide transparent warranty policies and after-sales support build significant trust with their clients. A procurement specialist from a large-scale mining operation stressed the importance of vendor transparency and support, emphasizing that their switch to a reliable supplier resulted in a 30% increase in pump uptime. In the competitive arena of industrial pumps, misinformation can be costly. Decision-makers should be wary of too-good-to-be-true claims and seek validation from third-party reviews and certifications. An experienced quality assurance manager highlighted that integrating reliable user reviews and case studies into procurement decisions led to smarter investments in pump covers that delivered consistent performance under demanding conditions. Finally, the future of sludge pump covers lies in innovation. From smart diagnostics embedded into the covers for real-time performance monitoring to the use of sustainable and recyclable materials, the industry is moving towards greener and technologically advanced solutions. A tech startup CEO emphasized a prototype cover equipped with IoT sensors to predict wear and tear, hence avoiding unexpected pump failures. In conclusion, selecting the right sludge pump cover is more than a mere purchasing decision—it's a commitment to operational excellence, safety compliance, and cost-effectiveness. Its importance is validated through expert experiences and professional insights, emphasizing the need for selecting components that promise performance, reliability, and minimal environmental impact. As industries evolve, staying informed and prioritizing quality over cut-rate alternatives will ensure the sustainability and efficiency of operations.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025