- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 15, 2025 15:36 Back to list

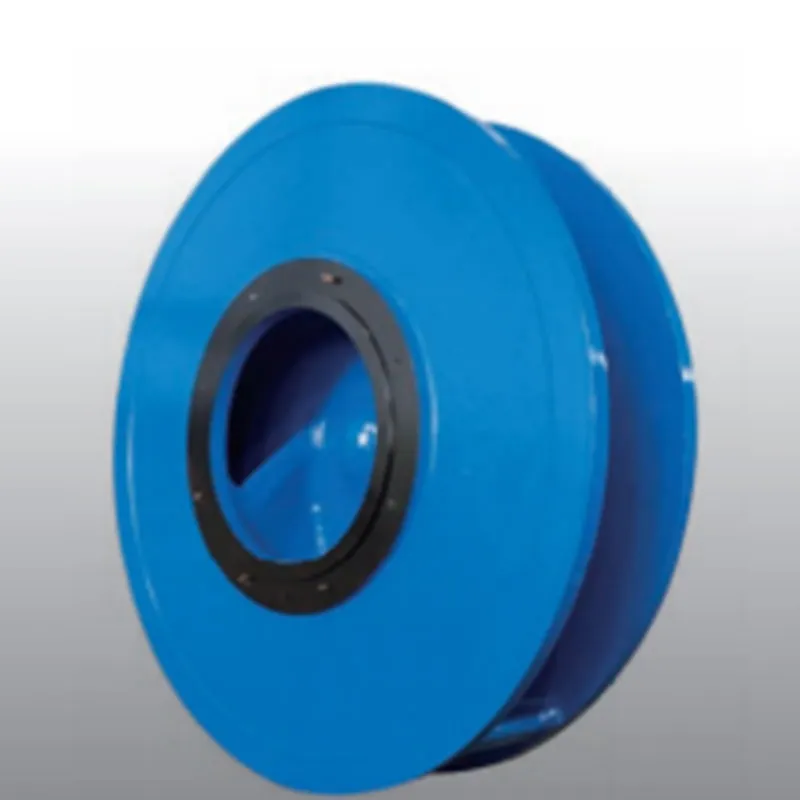

SP MODEL SUMP PUMPS APPLICATION AND FEATURES

Safety, an imperative in any industrial operation, is a focal point in the design of mobile screw compressors. They are equipped with a range of safety features, including automatic shutdown systems triggered by overloads, temperature anomalies, or other operational irregularities. These features not only protect the machinery but also safeguard operatives against potential hazards. In terms of expertise and authoritativeness, manufacturers of mobile screw compressors often provide extensive training and support for their products. This includes detailed manuals, troubleshooting guides, and expert consultations, ensuring that users have access to the requisite knowledge to operate and maintain these sophisticated machines effectively. Trustworthiness in this domain is reinforced by rigorous industry standards and certifications that validate the reliability and efficiency of these compressors. Manufacturers adhere to strict quality control measures during production, ensuring that every unit meets the highest standards for performance and durability. A consideration for businesses eyeing mobile screw compressors is the total cost of ownership. While initial investment might be higher compared to some alternatives, the long-term savings achieved through energy efficiency, reduced maintenance costs, and enhanced productivity provide a compelling case for their adoption. Finally, the adaptability of mobile screw compressors allows them to cater to a diverse array of applications. From powering pneumatic tools and blasting operations to ensuring operational continuity in manufacturing processes, their role across industries is expansive and invaluable. In conclusion, mobile screw compressors epitomize the blend of reliability, efficiency, and portability. Their design innovations, coupled with advanced operational features, render them a pivotal resource in myriad industrial environments. For businesses seeking to enhance operational efficiency while maintaining flexibility and minimizing costs, investing in a mobile screw compressor is undeniably a strategic move.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025