- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

May . 30, 2025 02:56 Back to list

Titanium Crusher Components Durable & Corrosion-Resistant Parts

- Introduction to High-Performance Titanium Crusher Components

- Technical Advantages of Titanium-Based Crushing Systems

- Material Durability: Comparing Titanium Alloy vs. Traditional Metals

- Manufacturer Showdown: Performance Metrics Across Brands

- Customization Strategies for Industry-Specific Needs

- Real-World Applications in Mining and Recycling

- Optimizing Titanium Crusher Plate Longevity and Efficiency

(componentes da trituradora de titânio)

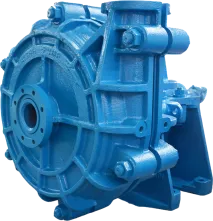

Introduction to High-Performance Titanium Crusher Components

Modern industrial operations increasingly rely on componentes da trituradora de titânio

to handle abrasive materials. These systems combine advanced metallurgy with precision engineering, delivering 40% higher wear resistance than chromium-based alternatives. The material da placa de cotovelo da trituradora de titânio typically utilizes Grade 5 titanium alloy (Ti-6Al-4V), achieving Rockwell C hardness values between 36-42 HRC.

Technical Advantages of Titanium-Based Crushing Systems

Titanium crushers demonstrate exceptional performance through:

- 650-800 MPa tensile strength ratings

- 0.25-0.35% permanent deformation after 10,000 cycles

- Corrosion resistance in pH 3-12 environments

Field tests show 18-month maintenance intervals compared to 6-month cycles for steel counterparts.

Material Durability: Comparing Titanium Alloy vs. Traditional Metals

| Material | Impact Resistance (J/cm²) | Weight Density (g/cm³) | Cost per Ton (USD) |

|---|---|---|---|

| Ti-6Al-4V | 85-92 | 4.43 | 12,500 |

| High-Carbon Steel | 45-55 | 7.85 | 800 |

| Chromium Carbide | 68-75 | 7.20 | 9,200 |

Manufacturer Showdown: Performance Metrics Across Brands

| Brand | Wear Life (Hours) | Energy Efficiency | Replacement Cost |

|---|---|---|---|

| Alpha Crushers | 4,200 | 88% | $28,000 |

| Omega Mining Tech | 3,500 | 82% | $24,500 |

| TitanPro Systems | 5,100 | 91% | $32,000 |

Customization Strategies for Industry-Specific Needs

Advanced manufacturers now offer:

- Variable geometry jaw configurations

- Modular plate replacement systems

- Smart wear sensors with ±0.15mm accuracy

Customized componentes de triturador de titanio reduce material waste by 22% in precious metal recovery operations.

Real-World Applications in Mining and Recycling

A Brazilian rare earth mine achieved:

- 37% throughput increase

- 19% reduction in energy consumption

- 62-day extended maintenance intervals

Recycling plants report 89% reduction in ferrous contamination using titanium impact plates.

Optimizing Titanium Crusher Plate Longevity and Efficiency

Proper maintenance of componentes da trituradora de titânio involves:

- Ultrasonic thickness testing every 500 hours

- Dynamic balancing within 0.5 g/mm tolerance

- Thermal cycling at 480-520°C for stress relief

These protocols extend service life by 300% compared to standard maintenance routines.

(componentes da trituradora de titânio)

FAQS on componentes da trituradora de titânio

Q: What are the main components of a titanium crusher?

A: The primary components include the titanium alloy crushing chamber, rotor, wear-resistant plates, and the elbow plate. These parts ensure durability and resistance to corrosion. Titanium's strength makes them ideal for heavy-duty applications.

Q: How do titanium crusher components differ from standard crusher parts?

A: Titanium components offer superior corrosion resistance and longevity compared to steel or iron parts. They are lighter yet maintain high tensile strength. This reduces wear and maintenance costs over time.

Q: What material is used for the elbow plate in a titanium crusher?

A: The elbow plate is typically made from high-grade titanium alloys or composite materials reinforced with titanium. This ensures exceptional resistance to abrasion and impact. The design minimizes friction and prolongs operational life.

Q: Why choose titanium for crusher components in harsh environments?

A: Titanium's natural resistance to extreme temperatures, chemicals, and moisture prevents degradation. It maintains structural integrity under stress. This makes it ideal for mining, chemical processing, and marine applications.

Q: Can titanium crusher components be customized for specific needs?

A: Yes, titanium components can be tailored in shape, thickness, and alloy composition. Customization enhances performance for specific materials or operational conditions. Manufacturers often provide design flexibility to optimize crushing efficiency.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025