- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 10, 2025 11:37 Back to list

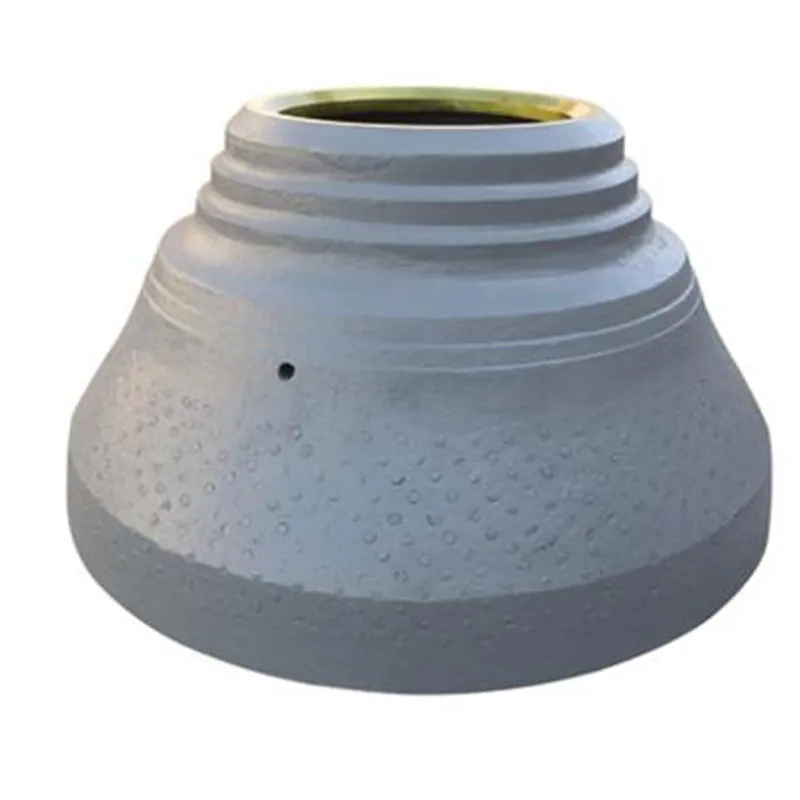

bombas químicas de lodo

With technology rapidly advancing, the future of chemical sludge bombs could include smart sensors and AI-driven optimizations to enhance process efficiencies. These technologies promise to further refine composition assessments and optimize conversion processes, thereby improving yield and sustainability metrics. To prevail in this developing arena, industry leaders should foster transparent research partnerships. Collaboration between academia and industry helps accelerate the development of standardized methodologies and best practices, ultimately driving broader acceptance and implementation across sectors. Finally, businesses need to maintain an open dialogue on the operational impacts and successes of chemical sludge bombs. Sharing outcomes, from reduced environmental impact to cost savings and energy outputs, is crucial, not only for nurturing trust among stakeholders but for encouraging further innovation. This continuous exchange of information, backed by solid data and shared experiences, fortifies industry credibility and collectively advances towards a sustainable, efficient future in waste management technology. The discussion surrounding chemical sludge bombs is just beginning, but establishing a robust framework built on proven expertise, authoritative oversight, and unwavering trust will ensure that these innovations play a pivotal role in sustainable industrial evolution.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025