- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Mar . 07, 2025 01:38 Back to list

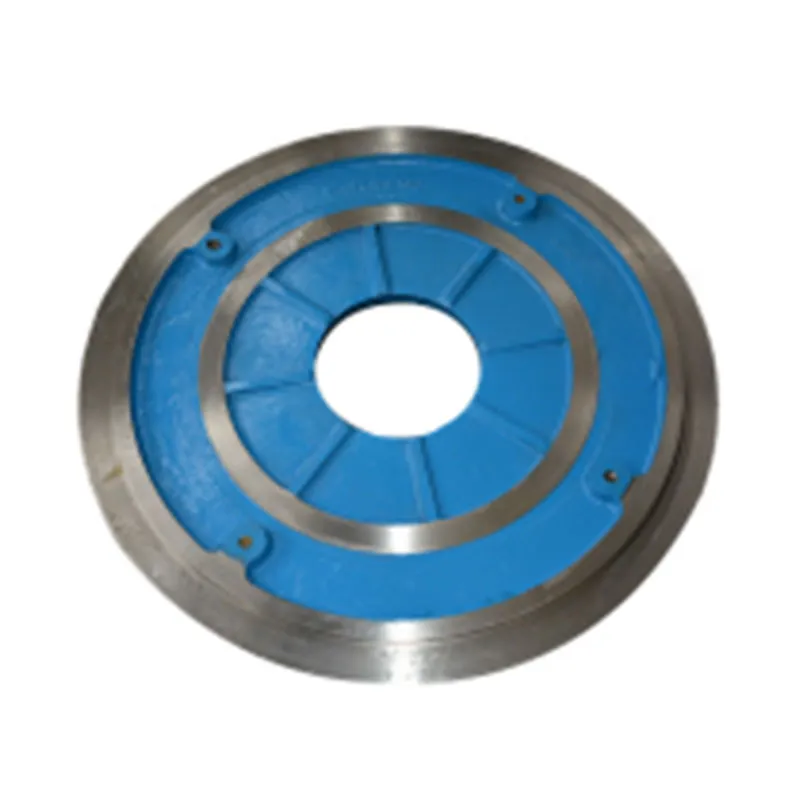

bombas de zircão

Industries searching for reliable and authoritative solutions often consider zirconium pumps as the preferred choice because of their proven track record in functionality and reliability. Renowned manufacturers offer informative resources and expert customer service to assist industries in selecting the appropriate pump model, ensuring maximum efficiency and cost-effectiveness tailored to specific operational needs. Trust in zirconium pumps is reinforced by rigorous testing and quality assurance processes that manufacturers implement to meet stringent industry standards. These processes certify that each unit delivers optimal performance in its respective application. The confidence provided by such thorough testing is essential for operations where even minor pump failures could result in significant downtime or safety hazards. Finally, turning to expert consultation can provide invaluable insights for industries considering integrating zirconium pumps into their systems. Leveraging the expertise of experienced engineers or technical consultants can aid in optimizing the layout and functionality of pumps within an industry’s existing infrastructure. Expert advice ensures that transition and integration processes are seamless, maintaining productivity while enhancing system robustness. In summation, zirconium pumps embody a blend of experience, expertise, authoritativeness, and trustworthiness. Their adoption signifies an intelligent choice aimed at bolstering the efficiency and longevity of industrial operations. Through their unmatched chemical resistance, thermal stability, mechanical strength, and sustainable attributes, zirconium bombas indeed represent the future in industrial pump technology, promising robust performance coupled with long-term economic and environmental benefits.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025