- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Feb . 11, 2025 01:28 Back to list

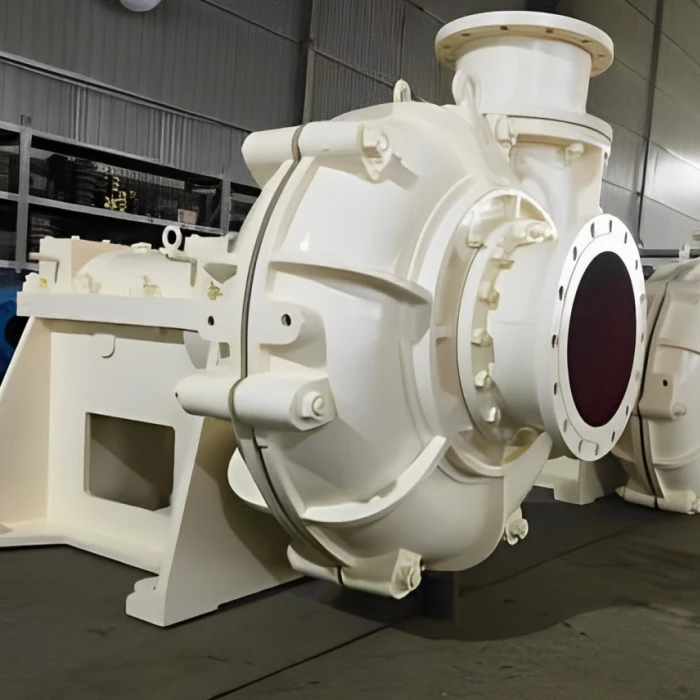

oem slurry pump cover

True experience in using OEM mud pumps is reflected in the operational advantages these tools provide. For instance, they are engineered to withstand intense workloads, which are common in drilling activities. Their robust build results in low vibration and noise, aspects that are crucial for maintaining a safe working environment. Additionally, OEM mud pumps often feature user-friendly interfaces, promoting ease of use and reducing the need for extensive training. One significant aspect of OEM mud pumps is their contribution to an operation's sustainability goals. High-quality, durable components mean longer intervals between replacements and repairs, reducing waste and resource consumption. OEM pumps are also generally more energy-efficient, reflecting a design philosophy that prioritizes both performance and environmental responsibility. In financial terms, investing in OEM mud pumps translates to long-term savings. Although initially more expensive than non-OEM alternatives, their durability and lower maintenance frequency reduce overall costs. Businesses can avoid hidden expenses associated with equipment failure, such as emergency repairs or replacements that can disrupt operational continuity. Moreover, a longer operational life means a better return on investment. In conclusion, OEM mud pumps offer a compelling package of reliability, performance, and long-term value. They embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness, forming the bedrock of successful and sustainable industrial operations. For decision-makers looking to enhance their equipment's efficacy and align with industry best practices, choosing OEM mud pumps is a straightforward decision that promises sustained performance and peace of mind.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025