- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Mar . 03, 2025 12:22 Back to list

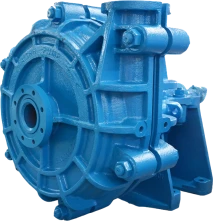

bombas de lama pesada

When it comes to installation and maintenance, having a team with considerable expertise ensures smooth operation and longevity of the pump. It is crucial to adhere to recommended installation guidelines, which often include details related to alignment, power supply, and plumbing. Regular maintenance practices, such as monitoring wear parts and checking seals and bearings, are vital to maintaining the pump’s reliability. Continuous advancements in pump technology have seen the integration of smart features, such as remote monitoring and IoT capabilities. These advancements provide operators with real-time data to make informed decisions and perform predictive maintenance, further enhancing the trustworthiness and efficiency of slurry pump operations. However, the very nature of pumping abrasive materials means that wear is inevitable. That’s why selecting a supplier with a proven track record and comprehensive support services is imperative. A reputable supplier offers not just the product, but also full lifecycle support, from installation through to maintenance and eventual replacement. Ultimately, heavy-duty slurry pumps are a testament to engineering excellence, balancing complexity with reliability. Their presence in industries underpins some of the most demanding processes, ensuring that harsh materials are moved efficiently and safely. Selecting the right pump not only requires a deep understanding of the specific application but also a commitment to quality and innovation from both suppliers and operators. In conclusion, the effectiveness of a heavy-duty slurry pump hinges on a blend of experience, professional expertise, and rigorous supplier standards. These components work in harmony to assure users that their critical operations will be conducted reliably and efficiently, making the decision to invest in high-quality slurry pumps not just beneficial, but essential for any heavy-material handling operation.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025