- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Bengali

- China

- China (Taiwan)

- Czech

- Danish

- Dutch

- English

- French

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- Miao

- Hungarian

- igbo

- Indonesian

- Italian

- Japanese

- Javanese

- Rwandese

- Korean

- Kyrgyz

- Lao

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Persian

- Polish

- Portuguese

- Punjabi

- Russian

- Spanish

- Swahili

- Swedish

- Telugu

- Vietnamese

Mar . 04, 2025 09:37 Back to list

Bowl Liner

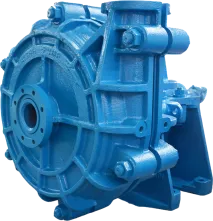

A vital consideration for choosing the right pump includes an authoritative understanding of the slurry’s rheological properties. Accurate measurement of particle sizes, solidity concentration, and fluid viscosity dictates the required pump power and speed. Investing in initial material testing, thereby understanding the nature of what’s being pumped, is crucial in selecting the most efficient pump configuration, avoiding the pitfalls of cavitation or impeller clogging. In today’s technology-driven landscape, cutting-edge monitoring systems are integral to the functioning of 12-inch slurry pumps. These systems provide real-time data feedback, enabling operators to adjust parameters dynamically to maintain efficiency and preempt potential failures. Supported by IoT advancements, modern slurry pumps benefit from remote monitoring capabilities, allowing for predictive maintenance which forestalls catastrophic breakdowns and lengthens the lifespan of the equipment. Ultimately, trust in 12-inch slurry pumps is built on a foundation of proven performance across diverse industries, stringent quality standards, and a commitment to continuous improvement informed by user feedback and technological advancements. Such pumps are crucial not only for performance stability but also for adherence to environmental and safety regulations that govern industrial operations worldwide. For entities reliant on fluid transportation systems, the informed selection and meticulous upkeep of these pumps are fundamental to achieving operational excellence. Therefore, when procuring a 12-inch slurry pump, it is a sound strategy to engage with reputable manufacturers and suppliers who demonstrate a profound understanding of both the technical specifications and the operational challenges of using these machines. Investing in units equipped with the latest technological innovations and supported by a network of dedicated service professionals promises durability and effectiveness, ensuring that capital investments translate into tangible productivity gains and compliance with international quality and safety standards.

-

Low-Cost Borehole Drilling Machine for Small-Scale Projects

NewsJul.11,2025

-

Carbide Bullet Teeth for Abrasive Formations: Powering Industrial Drilling Efficiency

NewsJul.11,2025

-

Advantages of Down-the-Hole Drill Bits in Geothermal Projects

NewsJul.11,2025

-

Hole Hammer Use in Water Well Drilling

NewsJul.11,2025

-

Benefits of a Mobile Diesel Compressor in Construction

NewsJul.11,2025

-

Benefits of Diesel Portable Screw Air Compressors

NewsJul.11,2025